Mixing Slurries 10x to 100x Faster with Resonant Acoustic Mixer (RAM) Technology

Mixing Slurries and pastes can be challenging. They are made up of solids in a liquid matrix. In some cases, a slurry can be processed similar to a dense liquid; however, in many cases, slurries present unique challenges during handling and processing.

Slurry properties must be well understood in order to process the mixture effectively, namely particle size and distribution as well as the tendency of the particles to settle and their tolerance for shear forces. These characteristics along with viscosity greatly impact the ability to achieve a homogeneous slurry mixture as well as the stability of the final product.

Challenges to Mixing Slurries

Attrition of solid particles is one of the key challenges with slurries. Traditional methods that utilize impellers create a potentially high shear mixing environment that damage particle integrity and reduce the particle size. Additionally, some solids are cohesive and tend to clump together, making uniform dispersion of the solids throughout the slurry even more difficult.

Once a slurry is blended and a uniform suspension of the solids throughout the liquid is achieved, slurries tend to be unstable and may separate during transport or storage. In general, the larger the solid particle size in a slurry, the more difficult it becomes to maintain a uniform suspension as the heavy solids tend to settle at the bottom of the vessel. Solids that collect in tanks or drains lead to plugs and time-consuming clean-up steps.

3 Processing Steps for Mixing Slurries - The Old Way

All slurries require 3 processing steps:

- wetting

- incorporation

- mixing

Traditional mixers require all the ingredients to traverse the entire vessel to repeatedly enter and exit a small, localized mixing area around the impeller to achieve proper mixedness.

RAM Mixing Technology Performs All 3 Slurry Processing Steps Simultaneously - The New Way

ResonantAcoustic® Mixing (RAM) technology is not limited by impellers and activates all ingredients immediately. RAM mixes everywhere in the vessel, all the time – performing all three steps simultaneously and consistently throughout the mixing vessel and reducing processing time by huge orders of magnitude.

RAM slurry mixers deliver highly homogeneous, high quality results significantly faster than traditional technologies.

RAM also accelerates slurry mixing by creating a phenomenon known as Faraday instabilities within the slurries mixer. The surfaces of ingredients become unstable, causing “fingers” and “cavities” to form at the liquid surface boundary or interface. This swiftly increases the surface area of the liquids and facilitates rapid and homogenous mixing of the solid and liquid ingredients. Click here to watch a video demonstrating the Faraday instabilities created within RAM mixers.

Particle attrition is a non-issue for RAM technology since it is a “non-contact” mixing method requiring no impellers, blades, or other engineered devices to cause mixing.

Since there are no internal devices that damage or destroy particles, RAM mixers preserve material integrity in the final product –regardless of material viscosity.

RAM Mixers Drive the Highest Quality Slurry Mixing Performance in the World

High quality slurry mixing performance requires thorough distribution of solids in the liquid matrix, and stable suspension conditions for consistent processing characteristics at any point in the slurry. RAM’s intense and pervasive processing facilitates solid particle separation and dispersion, improving suspension stability and performance. Solid particles that tend to agglomerate and fall out of suspension are better separated and thus stay in suspension for longer periods, in some cases permanently. The superior result of RAM mixing contributes to longer-term stability of slurries – resulting in improved product shelf life.

In order to mix slurries, conventional methods often require the “right” sequence of ingredient additions. RAM technology mixes throughout the entire vessel, immediately and continuously. RAM’s direct, multiple ingredient processing eliminates ingredient addition time, chance for addition error, and virtually eliminates individual ingredient vessel clean-up.

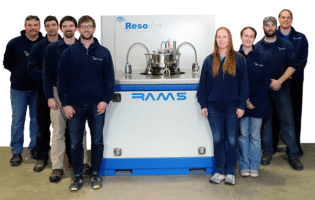

About Resodyn Acoustic Mixing

From the world's top pharmaceutical companies to international manufacturers, global tech giants, and nearly every U.S. National Laboratory, organizations in more than 40 countries rely on Resodyn ResonantAcoustic® Mixers’ single, powerful technology platform.

Whether used for development of new materials in a laboratory or for running full-scale industrial production, RAM systems are available in configurations to fit applications across dozens of industries.

Resodyn is the only company in the world to offer RAM Mixing Technology.

Change the way you think about slurries mixing and processing with a RAM demonstration: on line or on-site at your facility, using your own materials, and lets solve your mixing challenges.

Need help with a challenging slurry mix?

- We can do it 10x to 100x faster

- Zero cleaning, zero cross contamination

- Unbeatable mix uniformity

- It mixes in a way no other mixer can.

There is no better way to understand the RAM difference than seeing the technology in action. RAM sales professionals deliver high value, on-site, or on-video application presentations, product technology demonstrations, and even mixing tests using your own materials, without cost to you.

Contact us today to discuss your requirements or to schedule a free demo.