Home » Applications » Coating, Milling and Sieving

ONLY RAM MIXERS CAN MIX, COAT, MILL & SIEVE

ALL-IN-ONE MACHINE WITH UNBEATABLE RESULTS

IN AS LITTLE AS 8 SECONDS!

Coating & Surface Modification

ResonantAcoustic® Mixing (RAM) facilitates the even distribution of the coating material (such as powder or liquid) onto a substrate.

The acoustic energy ensures the coating particles are uniformly dispersed, especially for fine powders or liquids that require delicate handling. Some possible applications include:

- Uniform Dispersion: The resonant frequencies break up agglomerates or clumps, allowing the coating material to evenly spread across the surface.

- Reduced Mechanical Stress: If the coating process involves sensitive materials (like in pharmaceutical), RAM provides a gentler alternative to mechanical mixing or agitation, greatly reducing the risk of damaging the substrate.

Milling & Sieving

Milling and sieving is often used in pharmaceutical materials processing, and other industries benefit from the ability to mill particles with minimal impact on the integrity or desirable properties of materials being milled.

ResonantAcoustic® Mixing (RAM) allows for a unique milling and sieving system, one that does not rely on additives. RAM technology is unique in that it can operate effectively without milling media. This allows for the milling of materials normally too delicate for more traditional methods. It also eliminates undesired reactions between the processed materials and milling media, as is common with stainless steel grinding media. Here’s how RAM assists in achieving finer particle sizes or milling:

- Enhanced Material Breakdown: The sound waves generated by RAM create vibrations that break up solid materials, reducing particle size, improving the milling process by assisting in the even distribution of forces.

- Reducing Agglomeration: When milling fine powders, materials can form lumps or agglomerates. RAM reduces this issue by ensuring uniform dispersion and breaking up the clumps.

The RAM platform's rapid, 60Hz motion causes each particle to randomly collide with adjacent particles, diverting their paths, colliding and re-colliding with other particles behaving in equally chaotic fashion.

Similar or Dissimilar Particle Sizes

Chaotic particle collision and large scale vapor migration speed dispersion and ultra-high uniformity.

Particle Coating

Static and other physical forces combine to thoroughly coat particles, one material on another, layer upon layer.

Deagglomeration

Agglomerated materials are separated into uniform particles that are segregated rapidly with sieving attachments.

Milling, Size, & Morphology Changes

With the selection and addition of appropriate milling media, RAM can also be used to reduce particle size or change particle morphology.

Sieving

RAM technology can be used to separate mixed particles of varying sizes using common sieves. Low frequency operation speeds separation and flow-through of particles to cleanly and thoroughly segregate particles.

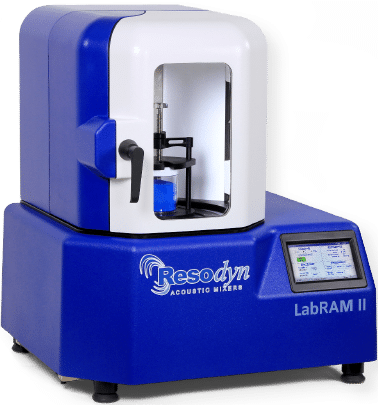

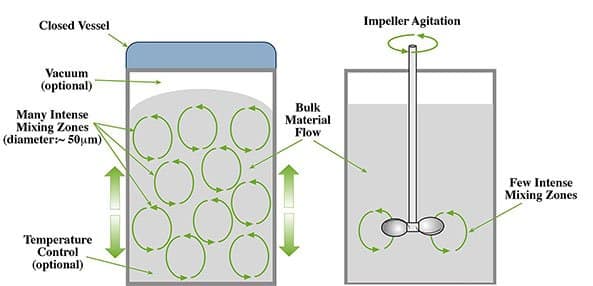

The Mechanics of RAM Mixing

RAM technology drives particle to particle collision and generates large-scale vapor migration, vastly improving both modes of mixing.

RAM technology drives particle to particle collision and generates large-scale vapor migration, vastly improving both modes of mixing.

ResonantAcoustic® Mixing:

- Vertical vessel movement 60 times per second at up to 100 g of acceleration generates intense particle motion.

- The primary mixing mechanism is particle redistribution driven by inter-particle collisions.

- Particle motion is entirely random, preventing de-mixing.

- Active vapor pockets move rapidly throughout the powder matrix creating highly active mixing zones (see chart).

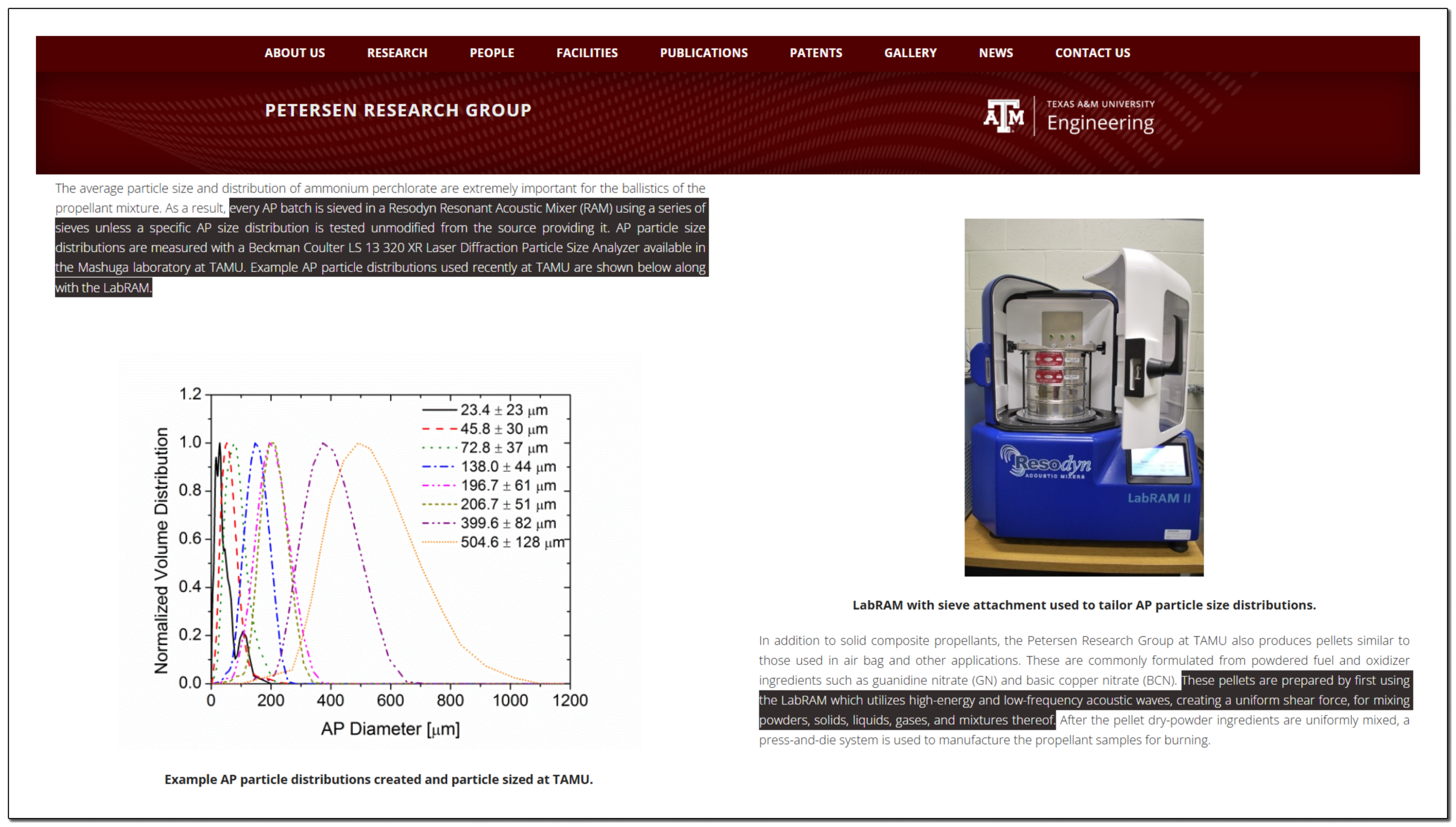

Client Testimonial: Sieving with RAM at Texas A&M University

Testimonials

“The use of a 96-well plate for nanomilling screening has been reported before using an orbital shaker, but long milling times of 24 h and at least 10 mg of drug compound per well were required. In contrast, the use of acoustic mixing reduces the processing time to <2 h on only 1–2 mg of drug compound per well. As a result, using a standard microtiter plate, 96 different formulation parameters can be evaluated in parallel in <2 h...

“With typical top down milling approaches, there is a limit to how concentrated the drug suspension can be before increases in viscosity result in decreased milling efficiency. At higher drug loadings, the naproxen suspensions become extremely viscous and formed a thick, solid paste that coated the impeller and prevented efficient milling from occurring... The acoustic milling approach allows for the preparation of high dose nanosuspension formulations that could not be obtained using conventional milling equipment.”

- A New and Improved Method for the Preparation of Drug Nanosuspension Formulations Using Acoustic Mixing Technology, Leung, D. et.al., Merck & Co. -International Journal of Pharmaceutics, 2014

"Sometimes drug-discovery labs have to use even smaller amounts of solid reagents when they are running hundreds of test reactions on a valuable organic molecule. “But there was no way to dispense solid reagents at such small scales as 0.1 mg,” says Ying Wang, who leads the high-throughput chemistry team at the pharmaceutical company AbbVie and helped develop ChemBeads.

Wang’s team makes ChemBeads by mixing a solid reagent with glass beads and then giving them a fierce shake using an acoustic mixer. The shaking helps the compounds and beads to stick together through van der Waals forces".

- M. Peplow, Chemical & Engineering News, March 27, 2019

"It’s very difficult to incorporate oxides into a metal with good dispersion. Before acoustic mixing, we had to perform a milling process that not only took days to complete, it was very messy and expensive. Using the LabRAM is a much cleaner process. We’re now able to incorporate oxides much faster and much more efficiently.”

- Materials Engineer, US Government Agency

Videos on Coating & Milling

Testimonial - AWE: Mixing and Milling with RAM

This video is 2 minutes and has detail about the Syntactic Composites application and Near-Net-Shape methods.

Dr. Nicholas Bazin of the Atomic Weapons Establishment UK (AWE) explains how RAM technology reduces the number of steps necessary for coating microglass baloons because it mills as it mixes.

Milling and Nano Coating in 8 Seconds

Coating larger particles with smaller ones is a common processing application, and milling is often a part of the same process. In this video, agglomerated carbon black particles are simultaneously milled to nano size particles that coat the plastic pellets completely in just a few seconds. The high speed video clearly illustrates the dispersion of carbon black particles, their de-agglomeration, and progressive and comprehensive coating of the plastic pellets.

NASA Invents GRX-810 SuperAlloy with RAM

NASA recently invented a new high temperature 3D-Printed GRX-810 superalloy with almost double the tensile strength, more than double the ductility, and orders of magnitude (10X-2000X) better creep rupture life than conventional superalloys and current 3D-printable metal parts.

GRX-810 cannot be produced by conventional machining, and is 3D-printed. GRX-810 can be used in space launch systems, heat exchangers in nuclear power plants and other extreme temperature environments, thanks to RAM technology.

GRX-810 is made by coating NiCoCr metal powder with a film of nanoscale Y2O3 oxide particles using RAM technology.

Prior attempts to mechanically alloy the Y2O3 onto the metal powder with traditional equipment had deformed the powder. It became more platelet-like, had a tendency to stick, and as a result was much more difficult to print.

RAM rapidly and powerfully, yet gently coats the metal powder with the ceramic, without deforming the powder. The powder remains very spherical and flows well through the 3D printer.

Client Testimonial - Abbvie

ChemBeads: chemistry coated in glass

What do tiny glass beads, a powder mixing machine and solid chemicals have in common?

Not much. Until a group of AbbVie chemists had an idea that could shorten the screening time for some compounds from weeks to days.

Long before there is a medicine, there is a compound. Or rather, thousands of compounds that must be tested in order to find the special few that could one day become a medicine. It’s a long and resource-heavy testing process to identify these “lead compounds” that could possibly be converted into a new medicine.

To test these compounds, scientists first have to make them. Unfortunately, finding the conditions necessary to make the desired compounds can often be a bottleneck, in part due to the limited amount of material available and a lack of technologies to screen diverse conditions efficiently and effectively. In other words, it adds a time consuming, resource-heavy step to what is already a painfully slow journey from scientific discovery to potential treatment.

After a few false starts, the team was inspired by a process where medicines are mixed with other inert materials to improve their solid characteristics. They found that glass beads can be coated with solid chemicals by combining them in a dry mixer. Solid chemicals are often very different from each other in terms of physical characteristics, but the chemical coated beads have very similar features, which makes a robot’s job much easier.

...our original RAM coating method is the most versatile for the broadest range of solids... - Impastato, A. C., Brown, J. T. C., Wang, Y., & Tu, N. P. (2023). Readily Accessible High-Throughput Experimentation: a general protocol for the preparation of ChemBeads and EnzyBeads. ACS Medicinal Chemistry Letters, 14(4), 514–520.

Watch Noah Tu, M.S., Senior Scientist, Discovery Chemistry and Technologies, AbbVie demonstrate the process:

Scientific Articles on Coating, Milling and Sieving

Efficient production of a high-performance dispersion strengthened, multi-principal element alloy

Scientific Reports

"Additive manufacturing currently facilitates new avenues for materials discovery that have not been fully explored. This new processing technique employed resonant acoustic mixing to coat an equiatomic NiCoCr powder with nano-scale yttrium oxides."

Smith, T. M., Thompson, A. C., Gabb, T. P., Bowman, C. L., & Kantzos, C. A. (2020). Efficient production of a high-performance dispersion strengthened, multi-principal element alloy. Scientific Reports, 10(1). https://doi.org/10.1038/s41598-020-66436-5

Applying dry powder coatings

PharmTech

"The LabRAM is a sophisticated bench-top mixer that exploits low frequency, high intensity, acoustic energy to rapidly fluidize and disperse as much as 500 g of a variety of materials."

Applying dry powder coatings. (2020, November 15). PharmTech. https://www.pharmtech.com/view/applying-dry-powder-coatings

Processing of reactive Ni−Al powders via the LabRAM**

Propellants, Explosives and Pyrotechnics

“Powder production limitations associated with HEBM, including the addition of process control agents, have inspired the exploration of an alternate manufacturing technique: acoustic dry milling with the Resodyn Laboratory Resonant Acoustic Mixer (LabRAM)... The method shows promise for the production of reactive powder for a host of applications.”

Jerke, M. R., Crawford, G. A., & Groven, L. J. (2024). Processing of reactive Ni−Al powders via the LabRAM**. Propellants Explosives Pyrotechnics, 49(4). https://doi.org/10.1002/prep.202300192

Halogen-bonded cocrystals via resonant acoustic mixing†

RSC Mechanochemistry

“However, an eleventh stoichiomorphic cocrystal of p-DITFB and TMP is obtained exclusively via RAM, suggesting that the combination of RAM and milling approaches may afford a broader exploration of the polymorphic and stoichiomorphic landscape than the use of a single technique in isolation.”

Nari, A., Ovens, J. S., & Bryce, D. L. (2024). Halogen-bonded cocrystals via resonant acoustic mixing. RSC Mechanochemistry, 1(1), 50–62. https://doi.org/10.1039/d3mr00028a

Mechanical and tribological performance of copper matrix self-lubricating composite prepared by resonant acoustic mixing powder

Tribology International

“CuNi-WS2 self-lubricating composites with 10 wt% WS2 were fabricated by combining resonant acoustic mixing (RAM) powders and pressureless sintering in an H2 atmosphere.”

Tu, Y., Zhu, X., Kang, X., Zhang, L., & Liu, C. (2024). Mechanical and tribological performance of copper matrix self-lubricating composite prepared by resonant acoustic mixing powder. Tribology International, 194, 109543. https://doi.org/10.1016/j.triboint.2024.109543

Resonant acoustic mixing (RAM) for efficient mechanoredox catalysis without grinding or impact media†

Chemical Communications

“RAM proceeds without formal grinding or impact media, is faster than the analogous ball-milling strategy, and is readily scalable.”

Effaty, F., Gonnet, L., Koenig, S. G., Nagapudi, K., Ottenwaelder, X., & Friščić, T. (2022). Resonant acoustic mixing (RAM) for efficient mechanoredox catalysis without grinding or impact media. Chemical Communications, 59(8), 1010–1013. https://doi.org/10.1039/d2cc06013b

Milling of Energetic Crystals with the LabRAM

Propellants, Explosives and Pyrotechnics

“This study focuses on the feasibility of safely dry milling micron-size energetic crystals on the LabRAM acoustic mixer, while optimizing milling parameters for effective size reduction.”

Kotter, L. N., & Groven, L. J. (2019b). Milling of Energetic Crystals with the LabRAM. Propellants Explosives Pyrotechnics, 44(7), 908–914. https://doi.org/10.1002/prep.201800327

Manufacturing superfine AP by milling in a lab-scale resonant acoustic mixer (LabRAM)

Journal of Energetic Materials

“Small AP particles (≤15 μm) are difficult to obtain from commercial vendors due to restrictions derived from increased explosion hazards for superfine AP (SFAP). An in-house SFAP manufacturing process was devised herein using resonant acoustic mixing (RAM).”

Rodriguez, F. A., Thomas, J. C., & Petersen, E. L. (2023). Manufacturing superfine AP by milling in a lab-scale resonant acoustic mixer (LabRAM). Journal of Energetic Materials, 1–13. https://doi.org/10.1080/07370652.2023.2219686

A New Approach for Preparing Stable High-Concentration Peptide Nanoparticle Formulations

Pharmaceuticals

“The subcutaneous administration of therapeutic peptides would provide significant benefits to patients... Each sealed well plate was then placed on a Resodyn LabRAM II Resonant Acoustic mixer (Resodyn Acoustic Mixers, Butte, MT, USA) and milled at 50 G acceleration for 2 h.”

Hu, C., Zang, N., Tam, Y. T., Dizon, D., Lee, K., Pang, J., Torres, E., Cui, Y., Yen, C., & Leung, D. H. (2023). A new approach for preparing stable High-Concentration Peptide nanoparticle formulations. Pharmaceuticals, 17(1), 15. https://doi.org/10.3390/ph17010015

The Production and Development of Acoustically Milled Reactive Ni-Al Composite Powders Consolidated via Cold Spray Deposition

Proquest

"The objective of this research was to evaluate acoustic milling as a reactive powder processing method by establishing relationships between milling parameters and the resulting reactive powder. The acoustically processed nickel-aluminum (Ni-Al) reactive powder was subsequently

consolidated to form a structural energetic material via hydraulic pressing and cold spray deposition."

Fesenmaier, M. P. (n.d.). The production and development of acoustically milled reactive Ni-AL composite powders consolidated via cold spray deposition - ProQuest. https://www.proquest.com/openview/daefe0420a536ff62e56d9779ac441b1/

Eco-friendly soft magnetic composites of iron coated by sintered ferrite via mechanofusion

Journal of Magnetism and Magnetic Materials

“Also the high-energy ball milling has been shown to be a potential, room temperature method for applying a coating to substrates inside milling vial [7], [14], [16]. Recently, the unique and simple dry particle coating route appears to be the resonant acoustic mixing, allowing the reduction of mixing time.”

Birčáková, Z., Onderko, F., Dobák, S., Kollár, P., Füzer, J., Bureš, R., Fáberová, M., Weidenfeller, B., Bednarčík, J., Jakubčin, M., Szabó, J., & Dilyová, M. (2021). Eco-friendly soft magnetic composites of iron coated by sintered ferrite via mechanofusion. Journal of Magnetism and Magnetic Materials, 543, 168627. https://doi.org/10.1016/j.jmmm.2021.168627

Picking up good vibrations: Exploration of the intensified vibratory mill via a modern design of experiments

International Journal of Pharmaceutics

“The aim of this work was to strengthen the understanding of the intensified vibratory mill by unravelling the milling process in terms of the particle size reduction and heat generation via a modern design of experiments approach... Originally commercialised as a mixing platform, the ResonantAcoustic® Mixing platform has been mostly employed as a dry mixing process, whereas its application in wet milling is less studied.”

De Cleyn, E., Holm, R., Khamiakova, T., & Van Den Mooter, G. (2021). Picking up good vibrations: Exploration of the intensified vibratory mill via a modern design of experiments. International Journal of Pharmaceutics, 598, 120367. https://doi.org/10.1016/j.ijpharm.2021.120367

Simple, scalable mechanosynthesis of metal organic frameworks using liquid-assisted resonant acoustic mixing

Chemical Science

“...We believe that the ability to form the ZIF-L product might be associated to LA-RAM (LabRAM) being a milder mechanochemical methodology, in which mechanical activation takes place by direct contact of reactant particles rather than through impact and abrasion by external milling media that are used in other types of mechanochemistry.

Importantly, in each of these cases [the LabRAM ResonantAcoustic® mixer] methodology appears to be superior to ball milling, which provided poorer control of product composition in the synthesis of a mixed-ligand MOF, and also did not yield ZIF-L...”

Titi, H. M., Do, J., Howarth, A. J., Nagapudi, K., & Friščić, T. (2020). Simple, scalable mechanosynthesis of metal–organic frameworks using liquid-assisted resonant acoustic mixing (LA-RAM). Chemical Science, 11(29), 7578–7584. https://doi.org/10.1039/d0sc00333f

Ball-Free Mechanochemistry: In Situ Real-Time Monitoring of Pharmaceutical Co-Crystal Synthesis by Resonant Acoustic Mixing

Chemical Communications

“...In marked contrast to ball-milling techniques, the lack of milling bodies in the RAM experiment does not hinder co-crystallisation of the two starting materials, which occurred readily and was independent of the frequency of oscillation...”

Michalchuk, A. a. L., Hope, K. S., Kennedy, S. R., Blanco, M. V., Boldyreva, E. V., & Pulham, C. R. (2018). Ball-free mechanochemistry: in situ real-time monitoring of pharmaceutical co-crystal formation by resonant acoustic mixing. Chemical Communications, 54(32), 4033–4036. https://doi.org/10.1039/c8cc02187b

Preparation of an Energetic-Energetic Cocrystal using Resonant Acoustic Mixing

Propellants, Explosives and Pyrotechnics

“...RAM was applied to the preparation of an energetic-energetic cocrystal comprised of CL-20 and HMX in a 2 : 1 mol ratio...the cocrystalline product from the RAM preparation is consistent with the product from solution crystallization...”

Anderson, S. R., Ende, D. J. A., Salan, J. S., & Samuels, P. (2014). Preparation of an Energetic‐Energetic Cocrystal using Resonant Acoustic Mixing. Propellants Explosives Pyrotechnics, 39(5), 637–640. https://doi.org/10.1002/prep.201400092

Oxide Milling and Blending Using a Resodyn® LabRAM Acoustic Mixer

“...in benchscale acoustic mixer autogenous size reduction studies using roll mill processed Cerium Oxide, testing showed no indication of significant particle size reduction. For double roll mill processed cerium oxide, homogeneity was observed throughout the cylindrical container after blending. Mixing on the LabRAM appeared to break up

most of the ‘pancake-shaped’ particles...”

Cauthen, C. J., Hoeffner, S., Clemson University Research Foundation, National Nuclear Security Administration, & NNSA Office of Defense Nuclear Nonproliferation. (2012). Oxide milling and blending using a Resodyn® LabRAM acoustic mixer. https://resodynmixers.com/wp-content/uploads/2022/03/Acoustic-Mixing-Final-Report-Rev-0.pdf

A New and Improved Method for the Preparation of Drug Nanosuspension Formulations Using Acoustic Mixing Technology

International Journal of Pharmaceutics

“... the development of acoustic mixing as a new and improved drug sparing method for the generation of drug nanosuspension formulations. This approach exhibits dramatic improvements in efficiency and time and materials savings, making it amenable for use in the early drug discovery and development space...”

Leung, D. H., Lamberto, D. J., Liu, L., Kwong, E., Nelson, T., Rhodes, T., & Bak, A. (2014). A new and improved method for the preparation of drug nanosuspension formulations using acoustic mixing technology. International Journal of Pharmaceutics, 473(1–2), 10–19. https://doi.org/10.1016/j.ijpharm.2014.05.003

Coating, Milling and Sieving Patents Made Possible by ResonantAcoustic® Mixing

WO WO2024218494A1 Alain You Li, Hui Luo, Maria Magdalena Titirici, Qilei Ssong & Dingchang Yang

Priority 2023-04-19 • Filed 2024-04-18 • Published 2024-10-24

Described herein is a process for recycling polyesters such as polyethylene terephthalate (PET) into terephthalic acid (TPA) and ethylene glycol (EG) using mechanical or acoustic energy coupled with a low temperature aging process. Also described herein is a process for electrolytic conversion of ethylene glycol (EG) into clean hydrogen (H2).

Highlighted Use: “In this example, a LabRAM II Resodyn acoustic mixer was used to depolymerise PET plastic into its monomers terephthalic acid (TPA) and ethylene glycol (EG).”

Nano silicone particulates, method to make them and articles therefrom

WO WO2023167931A1 Gregory Alan Marus, Meysam Shahami, Saheem Absar & Brandon Dang Advano, Inc.

Priority 2022-03-01 • Filed 2023-03-01 • Published 2023-09-07

Nanosized silicon or alloys thereof are formed by milling in solvents comprising at least one polar protic solvent (e.g., an alcohol) or polar aprotic solvent (e.g., a nitrile) where the average milling media size is at least about 5 times to 200 times larger than the initial average silicon particle size. The method more efficiently mills silicon and achieves smaller nanosized particles with less input power or time and stable dispersions in the absence of a surfactant allowing for the direct formation of secondary particles. The milled silicon particles are useful as electrodes in electrical devices such as batteries.

Highlighted Use: RAM mills silicon into nanoparticles.

Disordered rocksalt and cathode material and method of making it

WO WO2023235475A1 Tanghong YI Wildcat Discovery Technologies, Inc.

Priority 2022-06-03 • Filed 2023-06-01 • Published 2023-12-07

It has been discovered that improved disordered rocksalts comprise of Mn are made by method comprising mixing a lithium compound with a metal precursor compound comprised of Mn having an oxidation state of 2 to form a mixture and heating the mixture to a temperature to form a disordered rocksalt structure. The method may realize improved cycle life with altered metal and oxygen redox of the disordered rocksalt.

Highlighted Use: RAM mills the precursors to lithium oxide cathodes.

High-efficiency acoustic resonance mixing method for composite high-energy ball milling

CN CN115815607A Meng Xiangxu, Zhao Jiong, Zhang Yang, Zhao Yanjun, Hao Suye, Han Ruifeng, Wei Jun

Filed 2022-12-21 • Published 20203-03-21

The invention discloses a high-efficiency acoustic resonance mixing method of composite high-energy ball milling, which is characterized in that a spherical medium material with the diameter of 0.1-10mm is added into a raw material, the spherical medium vibrates violently together with powder during mixing, and the agglomerated powder is collided in the motion process, so that the effective crushing, deagglomeration and thinning of the agglomerated powder can be realized, and the effective dispersion can be further realized; meanwhile, before mixing materials, vacuumizing is carried out, so that deagglomeration of agglomerated powder can be assisted, and a uniformly mixed raw material can be finally obtained, and the requirement of an ultra-high performance superhard material product on high mixing uniformity of the raw material can be met; the superfine powder materials mixed by the method, such as superfine oilstone powder materials, wafer thinning grinding wheel powder materials and the like, can realize uniform distribution of superfine raw materials, meet the requirement of uniform mixing of products and further improve the product performance.

Highlighted Use: RAM provides a more efficient form of ball-milling for energetic materials

Mechanical system that continuously processes a combination of materials

US US9808778B2 Lawrence C. Farrar, Scott L. Coguill, Peter A. Lucon & Janice Lucon Resodyn Corporation

Priority 2012-05-31 • Filed 2013-08-13 • Granted 2017-11-07 • Published 2017-11-07

The present application is directed towards systems and methods for continuously reacting a combination of materials by use of an acoustic agitator and a continuous process vessel. The system can react, fluidize, mix, coat, dry, combine or segregate materials. The continuous processing system can include an acoustic agitator capable of being removably coupled to a continuous process vessel. The continuous process vessel can include a first inlet for introducing at least one process ingredient, a plurality of plates configured for directing a flow of the at least one process ingredient through the continuous process vessel and capable of transferring acoustic energy generated by the acoustic agitator into the at least one process ingredient, an outlet for discharging a product of the at least one process ingredient, and a fastener for removable coupling the continuous process vessel to the acoustic agitator.

Highlighted Use: RAM produces material over an extended period of time.

Sintered polycrystalline cubic boron nitride material

GB WO CN US WO KR JP CN GB2560641A Can Antionette, Myriam Megne Motchelaho Anne & Miranda-Fernandez Miriam Element Six UK LTD

Filed 2018-03-13 • Granted 2019-12-25 • Published 2019-12-25

A method of making a polycrystalline cubic boron nitride (PCBN) material comprises mixing matrix precursor powder having an average particle size of less than 250 nm and comprising an aluminium compound with 30 - 40 volume % of cubic boron nitride (cBN) having an average particle size of at least 4 µm and spark plasma sintering the mixture at a pressure of at least 500 MPa, a temperature of 1050 - 1500oC and a time of 1 - 3 minutes. The matrix material may further comprise any of titanium carbonitride, titanium carbide, titanium nitride, titanium diboride, aluminium nitride and aluminium oxide. The particles may be mixed using any of wet acoustic mixing, dry acoustic mixing and attrition milling. The cBN particles may have a multi-modal average size distribution.

Highlighted Use: RAM mixed aluminum and cubic boron oxide to create a polycrystalline matrix.

WO EP US ZA US10337256B2 Valeriy Konovalov & Abhijit Suryavanshi Diamond Innovations, Inc.

Priority 2015-01-23 • Filed 2016-01-21 • Published 2017-11-29

Polycrystalline diamond cutters for rotary drill bits and methods of making the same are disclosed. A polycrystalline diamond compact includes a polycrystalline diamond body having a working surface, an interface surface, and a perimeter surface. The polycrystalline diamond compact also includes a substrate bonded to the polycrystalline diamond body along the interface surface. A non-diamond volume fraction of the polycrystalline diamond body is greater at the interface surface than at the working surface.

Highlighted Use: RAM combined diamond and other powders to create a tougher, more stable mining drill bit.

Milling & Sieving Folio

For more patents and articles download our Milling and Sieving Folio below:

Milling & Coating White Papers

Get a FREE Demo of ResonantAcoustic® Mixing

We can schedule an on-site or online video demonstration with a LabRAM II (bench scale) mixer to show you the incredible versatility of RAM technology. We can mix any materials you wish to test, and the more challenging the mix, the better.

- Mix 10x to 100x faster

- Eliminate cleanup & cross contamination

- Exceptionally thorough and consistent mixing

- Available only through Resodyn