Home » Products

SOLUTIONS MATTER

RAM PRODUCTS DELIVER

Resodyn industrial mixing and processing products are made in the USA, operate in over 40 countries, and are becoming the processing technology of choice in industry after industry. All Resodyn Mixers feature universal processing technology for nearly any type of mixing.

ResonantAcoustic® Mixing Building Blocks:

START

Acoustics and Acceleration

Oscillating at up to 100x the force of gravity (acceleration) RAM technology generates unique material movement and sound-induced interaction delivering speed, quality, convenience, and safety.

EXPLORE

Unmatched Processing Versatility

The common RAM platform across all devices delivers the same performance for powders, liquids, slurries, and high viscosity pastes using the same core technology.

GROW

The Perfect Mix Scales Easily

RAM technology delivers direct scaling from bench to production levels with minimal or no adjustments in parameters or timing.

DISCOVER

New-to-the-World Solutions

RAM delivers new levels of efficiency and quality, leading to new product development, all at higher levels of productivity and profitability.

The ResonantAcoustic® Family of Mixers

Resodyn Acoustic Mixers deliver versatile, reliable, and repeatable performance in countless industrial applications from bench-scale development through continuous production.

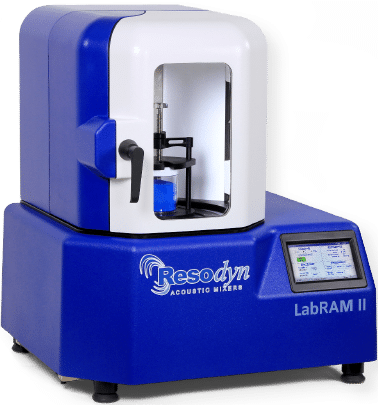

Dimensions

26" H x 19" W x 26" D

Weight

155 lbs. (70.3 kg)

Power Specs

100-120 / 200-240 VAC, (50-60 Hz), 1 Phase

LabRAM II

Up to 2.2 lb (1,000 gram) payload capacity full-featured, digitally controlled batch mixer for bench-scale development, mixing, and processing.

Dimensions

33" H x 29" W x 24 1/2" D

Weight

260 lbs. (117.9 kg)

Power Specs

100-120 / 200-240 VAC, (50-60 Hz), 1 Phase

OmniRAM

11 lb (5 kg) payload capacity, full featured, digitally controlled batch mixer for larger-than-bench-scale development, pilot and small-scale production and processing.

Dimensions

70" H x 75" W x 35" D

Weight

3200 lbs. (1,451.5 kg)

Power Specs

208-240 VAC, (50-60 Hz), 1 Phase

RAM 5

80 lb (36 kg) payload capacity, digitally controlled, batch mixer with multiple processing capabilities and options for pilot production and processing.

Dimensions

60" H x 90" W x 72"

Weight

8000 lbs.

Power Specs

400 VAC, 50 Hz, 3 Phase

480 VAC, 60 Hz, 3 Phase

RAM 55

With the batch payload capacity of up to 924 lbs (420 kg) RAM 55’s digitally controlled, multiple processing capabilities multiply RAM’s value through direct and easy scale-up from bench development to large scale batch production.

Dimensions

10.5' H x 15' W x 20' D

Power Specs

400 VAC, 50 Hz, 3 Phase

480 VAC, 60 Hz, 3 Phase

Continuous Acoustic Mixing (CAM), systems are configurable for OmniRAM, RAM 5, and RAM 55. CAM systems are custom built for the application and enable high throughput acoustic mixing of powders, pastes, and liquids.

PHARMACEUTICAL MIXERS

Resodyn Acoustic Mixers are rapidly becoming the processing technology of choice in the development and production of pharmaceutical products from bench-scale compounding and development through continuous high-throughput production.

PharmaRAM I

Up to .7 lb (300 gram) capacity batch mixer with efficient and easy-to-use controls ideal for pharmaceutical compounding operations.

Dimensions

32" W x 30" D x 32" H

Weight

153 Pounds (69.4 kg)

Power Specs

110/220 VAC, 50/60 Hz

PharmaRAM II

2.2 lb (1,000 gram) payload capacity, full-featured, digitally controlled batch mixer for bench-scale pharmaceutical development, processing, and testing.

Dimensions

32" W x 30" D 33" H

Weight

260 pounds (118 kg)

Power Specs

110/220 VAC, 50/60 Hz

OmniRAM Pharma

11 lb (5 kg) payload capacity, full-featured, digitally controlled batch mixer for larger than bench scale development, clinical trials, pre and small-scale production and processing.

Dimensions

70" H x 75" W x 35" D

Weight

3200 lbs. (1,451.5 kg)

Power Specs

208-240 VAC, (50-60 Hz), 1 Phase

RAM 5 Pharma

80 lb (36 kg) payload capacity, digitally controlled, batch mixer with multiple processing capabilities and options for clinical trials, pre and small-scale production and processing.

Dimensions

60" H x 90" W x 72"

Weight

8000 lbs.

Power Specs

400 VAC, 50 Hz, 3 Phase

480 VAC, 60 Hz, 3 Phase

RAM 55 Pharma

With the batch payload capacity of up to 924 lbs (420 kg) PharmaRAM 55’s digitally controlled, multiple processing capabilities multiply RAM’s value through direct and easy scale up from the bench development to larger scale batch production.

Dimensions

10.5' H x 15' W x 20' D

Power Specs

400 VAC, 50 Hz, 3 Phase

480 VAC, 60 Hz, 3 Phase

Continuous Acoustic Mixing (CAM) systems are configurable for OmniRAM, RAM 5, and RAM 55. CAM systems are custom built for the application and enable high-throughput acoustic mixing of powders, pastes, and liquids.

ENERGETICS AND HAZARDOUS MATERIAL MIXERS

Resodyn Acoustic Mixers have become the processing technology of choice in the development and production of energetics materials for propellants, explosives, and pyrotechnics. Resodyn "H" series mixers are designed specifically for safe processing of sensitive and hazardous materials.

LabRAM II H

Up to 2.2 pound (1,000 gram) payload capacity, full-featured, digitally controlled, batch mixer for bench scale development, mixing, and processing of hazardous and energetic materials.

Dimensions

27″ H x 32″ W x 30″ D

Weight

310 lbs.

Power Specifications

100-120 / 200-240

VAC (50-60 Hz)

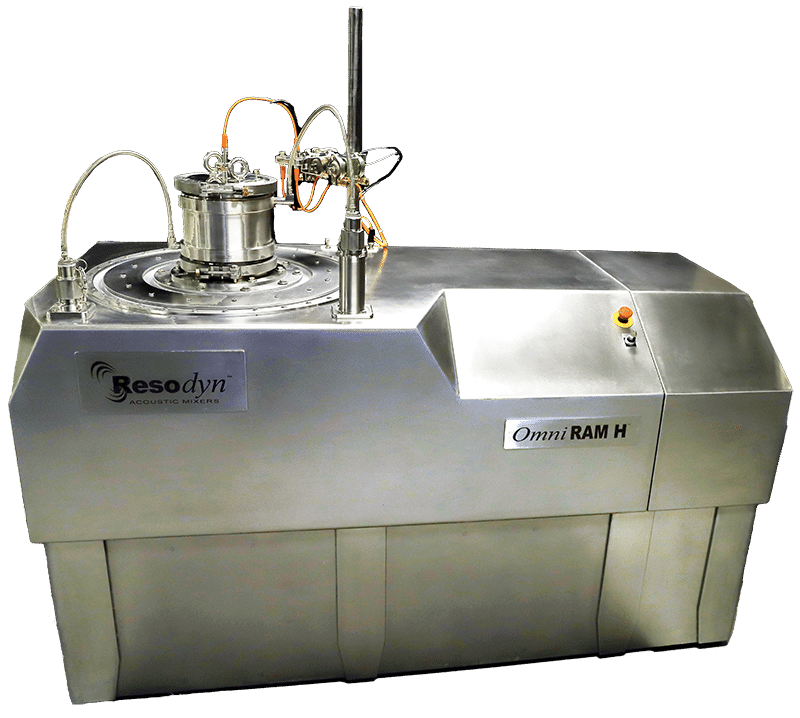

OmniRAM H

Up to 11 lb (5 kg) payload capacity, full-featured, digitally controlled, batch mixer for larger than bench scale development, pilot and small-scale production and processing of hazardous and energetic materials.

Dimensions

42″ H x 75″ W x 35″ D

Weight

3,200 lb (1,451.5 kg)

Power Specifications

208-240 VAC/1 Phase

(50/60 Hz)

RAM 5 H

Up to 80 lb (36 kg) payload capacity, digitally controlled, batch mixer with multiple processing capabilities for pre and small-scale production and processing of energetic and hazardous materials.

Dimensions

72” H x 80” W x 60” D

Weight

Configuration Dependent

Power Specs

400-460 VAC/3 Phase

(50-60 Hz)

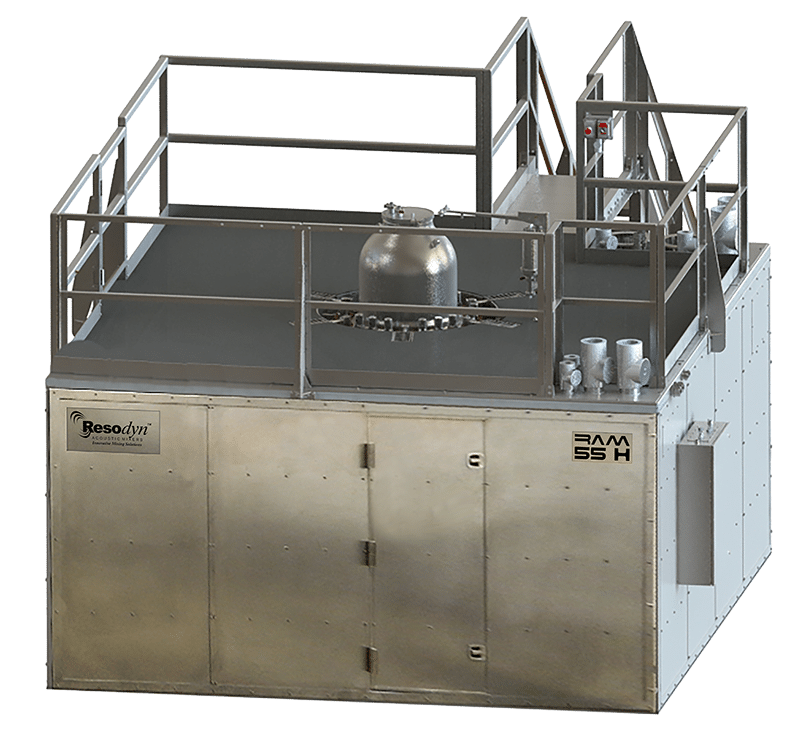

RAM 55 H

With the batch payload capacity of up to 924 lbs (420 kg) RAM 55 H’s digitally controlled, multiple processing capabilities multiply RAM’s value through direct and easy scale up from the bench development to larger scale batch production of energetic and hazardous materials.

Dimensions

10.5’ x 15’ x 10’

Weight

Configuration Dependent

Power Specs

480/VAC 60 Hz/3 Phase

Continuous Acoustic Mixing (CAM) systems are configurable for OmniRAM, RAM 5, and RAM 55. CAM systems are custom built for the application and enable high-throughput acoustic mixing of powders, pastes, and liquids.

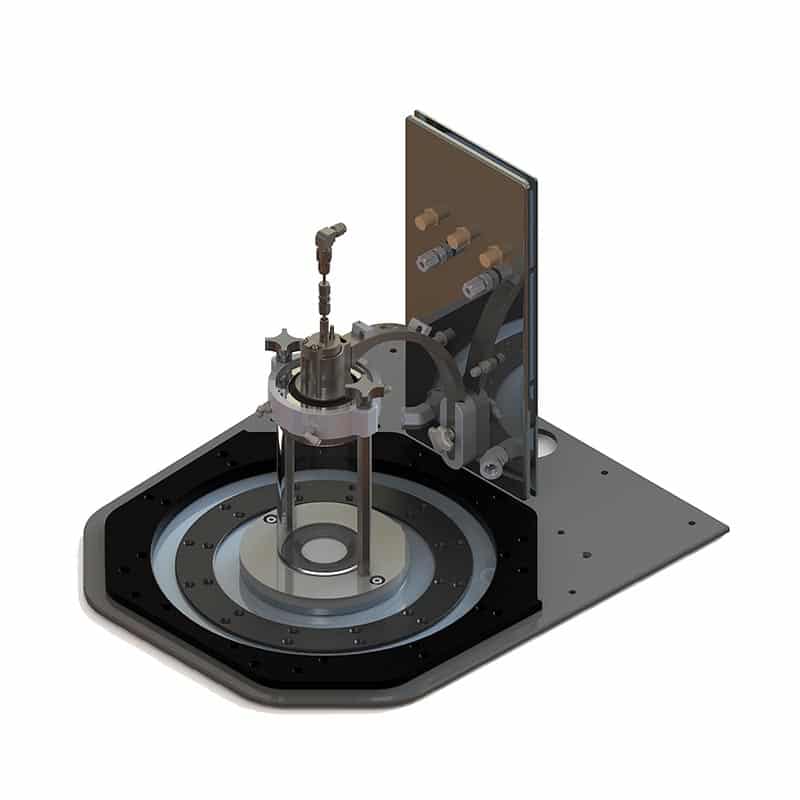

PROCESSING ACCESSORIES

The capabilities and efficiency of Resodyn Acoustic Mixers can often be expanded with complimentary processing accessories.

Automatic Vacuum System

Automated, recipe-based vacuum control for virtually any materials processing.

Compatible with:

LabRAM I, LabRAM II, PharmaRAM II

Manual Vacuum System

Manual, recipe-based vacuum control for virtually any materials processing.

Compatible with:

LabRAM I, LabRAM II, PharmaRAM II

Jacketed Vessel

Integrated temperature monitoring and control from 302°F (150°C) heating to 0°F (-18°C), 16 oz. (473 ml). Jacketed Vessel systems can be used with a variety of capacity liners, Resodyn vacuum systems, and optional chiller / heater units.

Compatible with:

LabRAM II, PharmaRAM II, LabRAM II H

Spray Coating System

The spray coating system takes advantage of LabRAM particle movement and vacuum capability combined with fine, ultrasonically generated mist to coat particles.

Compatible with:

LabRAM II, PharmaRAM II