The World's Most Advanced Material Processing

Mix, Coat, Mill, and Sieve Faster, Gentler, and Safer than Ever Before

500+

Published research papers prove RAM’s superiority

20+

Years of innovation

40+

Countries worldwide utilize RAM technology

1,000+

Machines sold

5M+

Hours of runtime

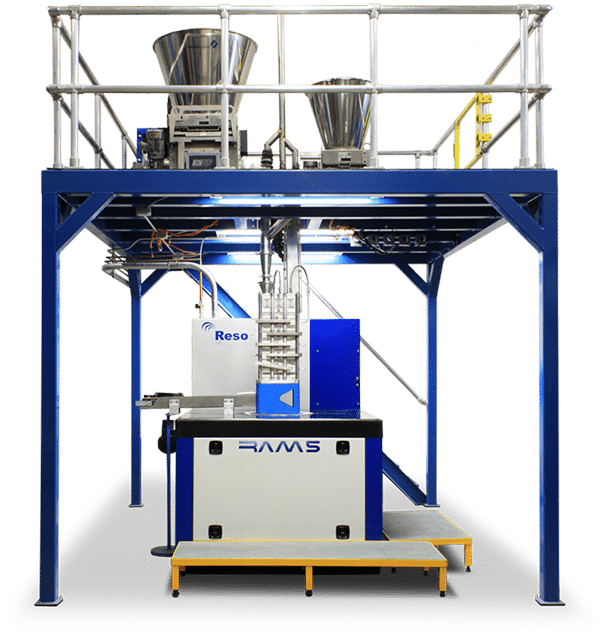

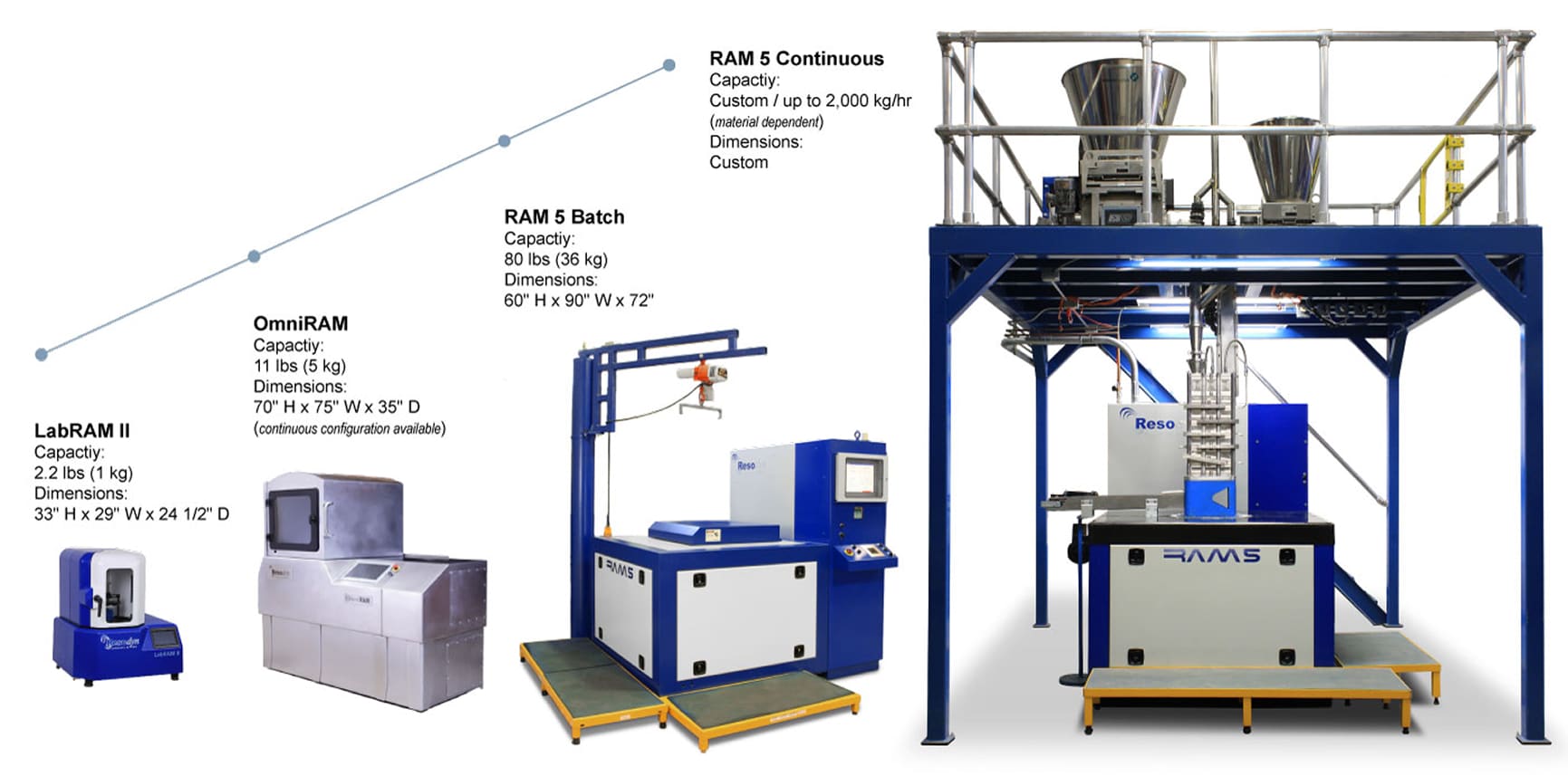

From the Lab Bench to the Production Floor

Seamless scaling from lab to production. Mix recipes stay consistent. Scaleup risks are mitigated.

Mix Virtually Anything

Powders, Slurries, Viscous Pastes, & Liquids

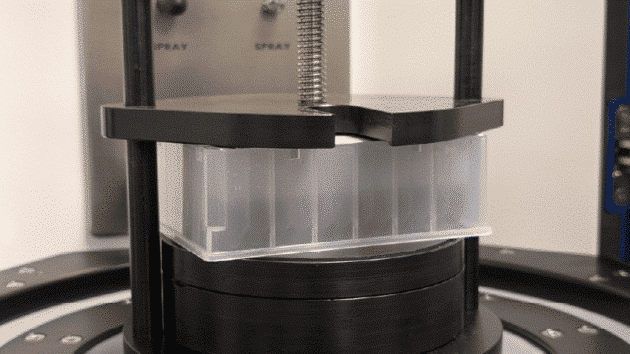

ResonantAcoustic® Mixing homogeneously blends virtually any combination of materials using rapid vertical displacement and low frequency sound energy. The result is breakthrough mixing speed, quality, and repeatability.

Real-World Proven Results

See what our customers are saying

"Mixing was taking six hours on a planetary mixer. With RAM, mixing and milling is accomplished as one process that takes only 2-3 minutes”

"Revolutionary... Fast... Accurate... GAME CHANGING.”

“From eight hours with an overhead stirrer to two minutes with Resodyn.”

“... RAM gives us a QUICK, EASY, AND CONVENIENT method

of mixing in a single unit...”

Mix 10-100X Faster

Harnessing the power of sound to generate unparalleled efficiency for the most complex of mixing needs.

Our patented technology effectively and efficiently processes any combination of powders, pastes and liquids with breakthrough speed, exceptional uniformity and repeatability. Our technology saves time in 3 ways:

- Much faster mixing, coating, and milling

- Reduced or eliminated processing steps

- Reduced or eliminated scrap and remixing. Do it once, do it right with RAM.

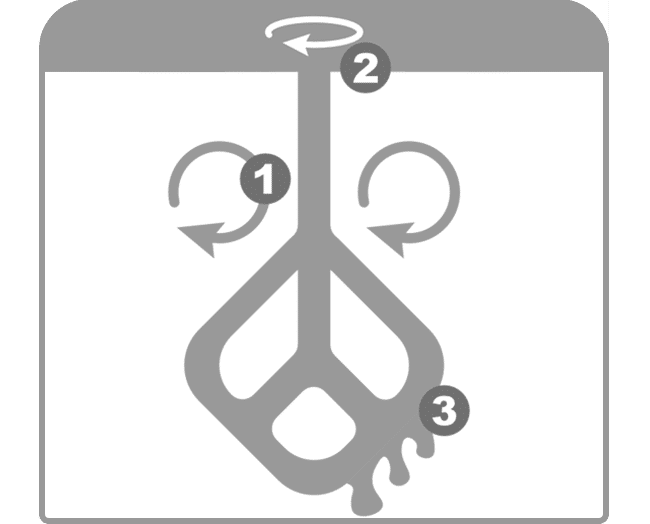

Conventional Mixing

- Few intense mixing zones

- Impeller agitation

- Difficult cleaning and high waste

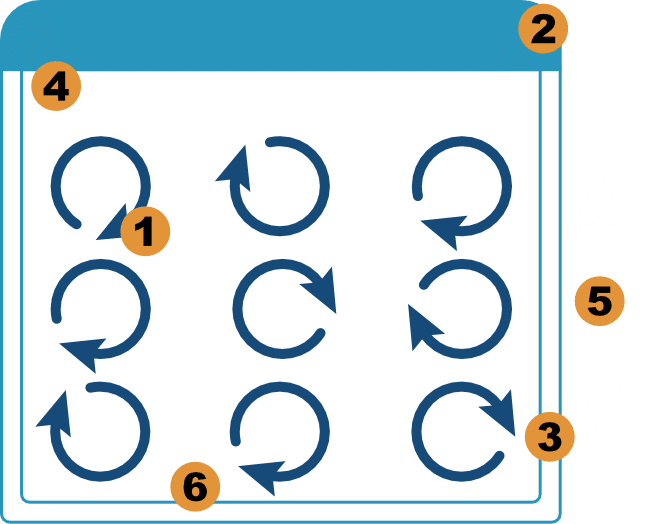

ResonantAcoustic® Mixing

- Many intense mixing zones

- Closed vessel (continuous flow optional)

- Temp control optional

- Vacuum optional

- Vertical oscillation

- Easy cleaning and reduced waste

Industry Applications

Additive Manufacturing (3D Printing)

Best-in-class mixing/blending technology for manufacturers of metal, ceramic and polymer 3D printing materials.

Learn More ›

Aerospace Adhesives & Sealants

RAM rapidly and thoroughly mixes polymers, fillers, curing agents, and additives under controlled temperature 10x-100x faster than traditional blenders.

Learn More ›

Battery & Energy Storage

RAM is particularly effective for battery processing because of its unique ability to achieve uniform, high-quality blends without damaging sensitive materials.

Learn More ›

Pharmaceuticals

Resonant Acoustic Mixing (RAM) technology mixes powders, liquids, and semi-solids efficiently, precisely, and gently—without the drawbacks of traditional mixing methods.

Learn More ›Featured Products

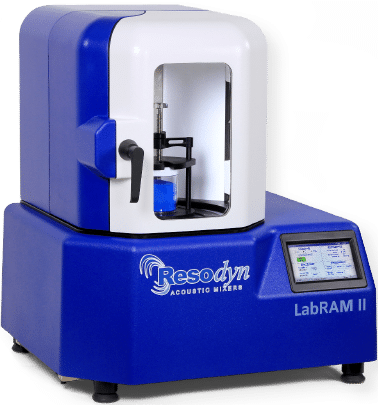

LabRam II

Up to 2.2 lb (1,000 gram) payload for bench-scale development, mixing, and processing.

Learn More

Latest News in RAM Technology