-

10-100X FASTER Mixing Times

-

Bladeless, Non-Contact Mixing

-

Consistent Homogenization

-

Repeatable

-

Scalable

-

Durable

-

Reliable

-

Eco-Friendly Operation

-

Unparalleled Safety

-

Custom Engineered Systems

-

Operational Cost Savings

-

Enables Innovation

Traditional Processes

RAM Results

HIGH VALUE INDUSTRIAL COATING

10.5 Hours Per Batch

53 Process Cycles

0.5 Hours Per Batch

3 Process Cycles

PRECISION DOSE MEDICAL MATERIAL

4 Hour Production Cycle

3 Processing Systems Used

1 Hour Production Cycle

1 RAM 5 System Used

PROPELLANT PRODUCTION

Multiple Systems, 6 Stages

Limited Production Capacity

Single RAM 5 System, 4 Stages

600% Added Production

MULTI-PRODUCT SECURITY DEVICES

High Labor Cost

High Scrap Rate

71% Reduction in Labor Costs

50% Reduction in Scrap Costs

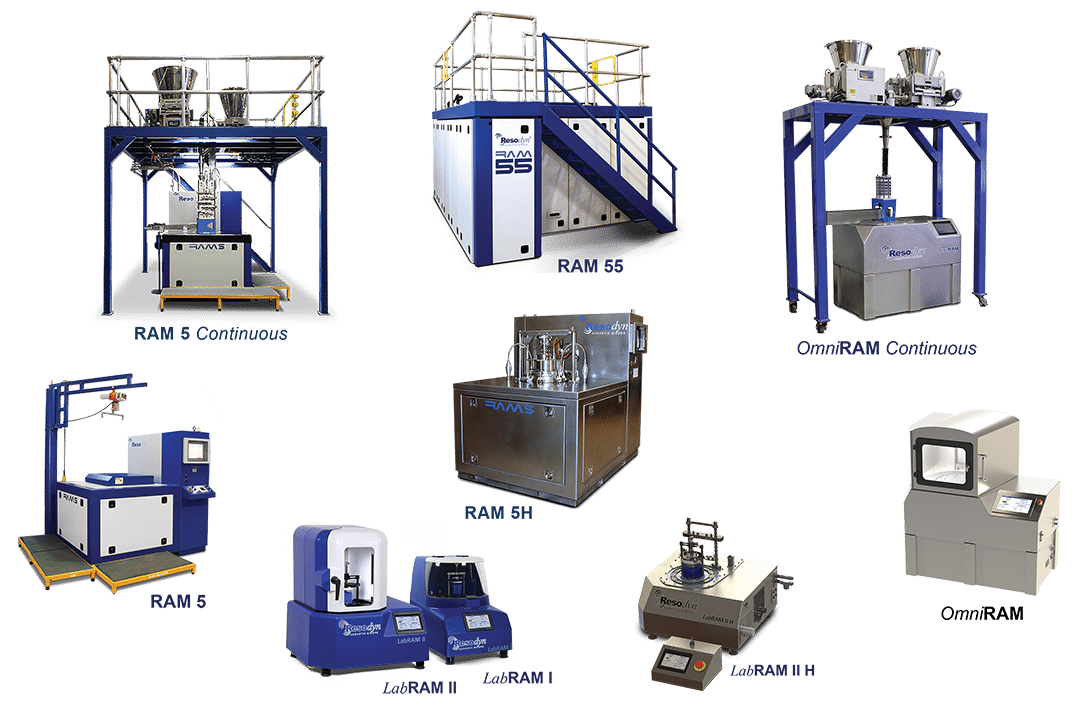

MIX VIRTUALLY ANYTHING

AT NEARLY ANY SCALE

ResonantAcoustic® Mixing mixes virtually any combination of materials from bench to production. RAM’s patented technology platform uses sound energy to effectively and efficiently process powders, pastes, liquids, and combinations thereof with breakthrough speed, quality, and repeatability.

Follow the link below that is closest to your material to see what RAM can do for you, or click here to see all RAM applications.

ResonantAcoustic® Mixing (RAM) Revealed

Discover the principles that drive RAM performance. From rapid vertical displacement to low frequency sound energy, and the “secrets” of resonance, RAM harnesses and combines common phenomena to introduce and deliver ground-breaking results to virtually any industry.

FROM BENCH DEVELOPMENT

TO INDUSTRIAL PRODUCTION

From the world's top materials companies, to international manufacturers, global tech giants, and nearly every U.S. National Laboratory, Resodyn Acoustic Mixer installations encircle the globe on a single, powerful technology platform.

Manufactured in the USA, ResonantAcoustic® Mixer products are installed in more than 35 countries.

Whether developing new materials in the laboratory or running full-scale industrial production, RAM systems are available in configurations to fit your application.

FEATURED PRODUCTS

FREE HELP

TO GET STARTED

RAM sales professionals deliver high value, on-site application presentations, product technology demonstrations, and even mixing tests using your own materials, without cost to you. Contact us today or specify when and how to contact you to discuss your requirements.

THE LATEST NEWS IN

RAM TECHNOLOGY

EXPERIENCE RAM PERFORMANCE FOR YOURSELF

FREE MIX TESTS AND DEMONSTRATIONS

Change the way you think about mixing and processing with a RAM demonstration, on-site at your facility, using your own materials, solving your mixing challenges. Free, and more rigorous mixing tests can also be scheduled in our mixing laboratory.