Frequently Asked Questions (FAQ) on Resonant Acoustic Mixing

Q. What makes RAM different from traditional industrial mixers?

A. Conventional bladed mixers often struggle with materials of varying viscosities or particle sizes. Their mechanical action can introduce excessive shear forces, generate heat, and degrade sensitive materials.

RAM’s patented, bladeless ResonantAcoustic® Mixing technology eliminates these problems by offering:

● Dramatically faster mixing times

● Reduced shear force and minimal overheating

● Consistent homogenization

● Repeatable results batch after batch

___________________________________________________________________________________________________________________________________________________________________________

Q. Where has RAM been successfully implemented?

A. ResonantAcoustic® Mixing is used in over 40 countries across a wide range of industries, trusted for its reliability and results.

___________________________________________________________________________________________________________________________________________________________________________

Q. What industries does RAM service?

A. Greater than 20 distinct industry markets have adopted RAM technology as a standard industrial mixing - processing practice. Each industry has specific requirements with countless individual applications.

Primary industries for Resodyn Acoustic Mixers, Inc. include:

● Energetic Materials (munitions, propellants, explosives, and pyrotechnics)

● Pharmaceutical Products

● Energy Storage/Battery Material Processing

● Chemical Production

● Adhesives & Sealants (Aerospace and Defense)

● R & D Services

● Highly Viscous Materials

● Specialty Products

___________________________________________________________________________________________________________________________________________________________________________

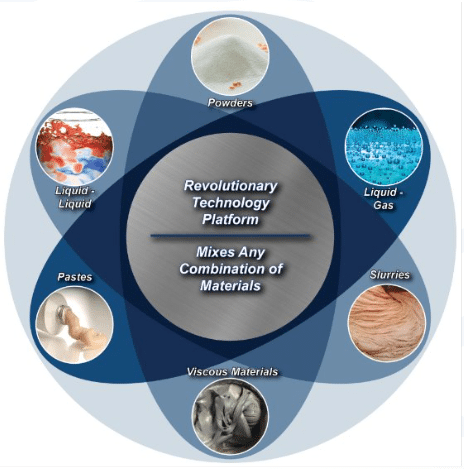

Q. What materials can RAM mix?

A. RAM systems are highly versatile and can mix nearly any combination of solids, liquids, and gases — especially where traditional mixers fail.

Applications include:

● Deagglomeration

● Sieving

● Coating

● High-viscosity blends

___________________________________________________________________________________________________________________________________________________________________________

Q. What sizes are available?

A. ResonantAcoustic® Mixers range in size from bench scale batch production models - to ongoing production capacity of up to thousands of kg/hour.

● LabRAM I - (500g payload capacity)

- Bench Scale

● RAM 55 - (420 kg payload capacity)

- Continuous Acoustic Mixing

___________________________________________________________________________________________________________________________________________________________________________

Q. What is the most popular model of RAM?

A. To date, the company has sold more LabRam II than any other model.

● Bench scale unit

___________________________________________________________________________________________________________________________________________________________________________

Q. What is the largest RAM batch system currently in operation?

A. The ResonantAcoustic® Mixer 55 (RAM 55) at the McAlester Army Ammunition Plant in Oklahoma (U.S.A.).

The RAM 55 is the largest batch system design currently offered by the company.

___________________________________________________________________________________________________________________________________________________________________________

Q. Is it scalable?

A. Yes!

RAM delivers a universal platform from bench scale to pilot scale through continuous production which provides consistent performance for scale up and technological development.

___________________________________________________________________________________________________________________________________________________________________________

Q. How is RAM powered?

A. Depending on the model, RAM units are operated by standard 110v, 220v, or 480v (3 phase) power supplies.

___________________________________________________________________________________________________________________________________________________________________________

Q. How will RAM work for my materials?

A. Resodyn Acoustic Mixers, Inc. sales team provides both on-site and virtual mixing demonstrations.

● Complimentary lab mix testing is also available!

For proprietary blends, the company maintains an equipment rental program (LabRAM I & II).

● Allows for material process testing in the privacy of your own facility.

___________________________________________________________________________________________________________________________________________________________________________

Q. What type of vessel (container) is required to mix in?

A. Bench scale systems can accommodate any rigid container.

● Glass

● Metal

● Plastic

Production scale systems are more specific, Resodyn Acoustic Mixing, Inc. will provide product specific vessels for use with each model.

___________________________________________________________________________________________________________________________________________________________________________

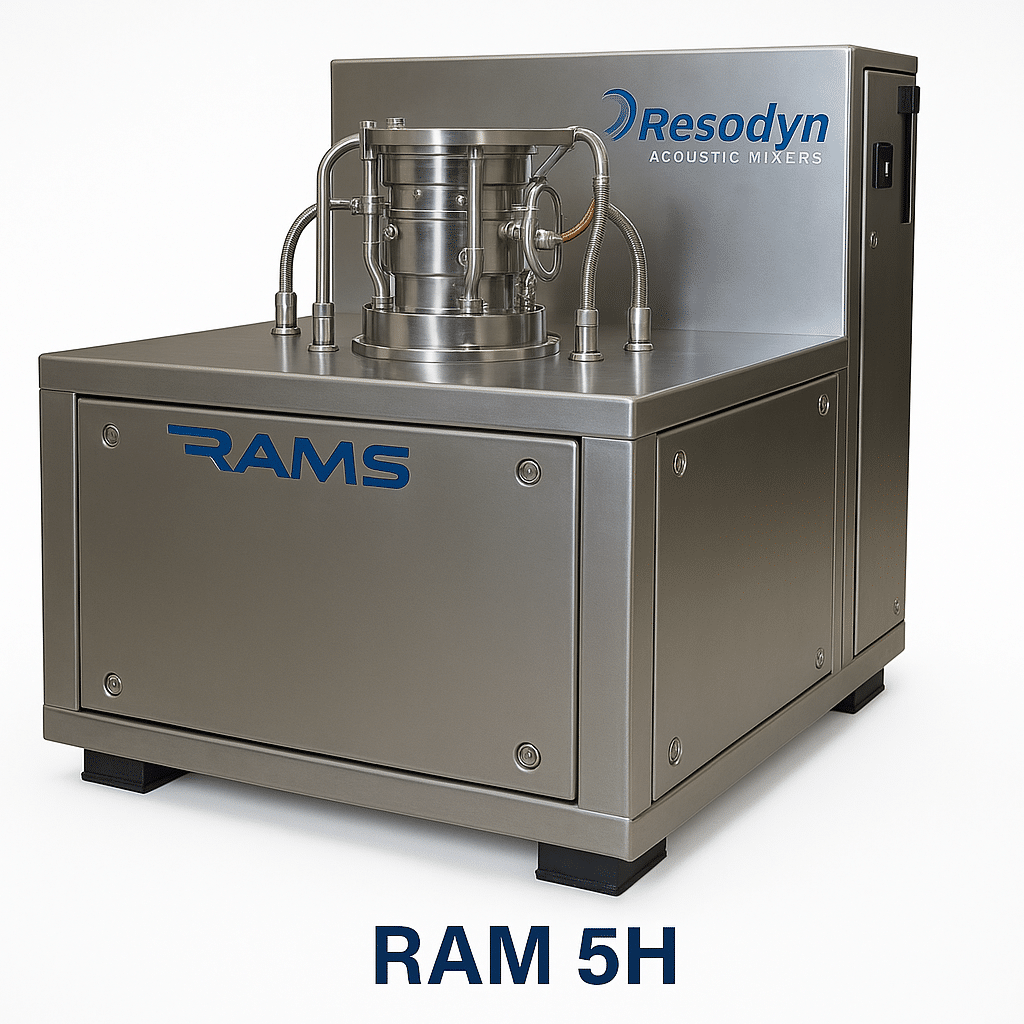

Q. Can RAM safely process hazardous materials?

A. Yes!

The ResonantAcoustic® Mixer H (RAM H) are available specifically for hazardous material mixing applications.

● Class I Div. 1 & Class II Div. 1 Safety Rated for hazardous material processing.

● Constructed of stainless steel.

● Redundantly grounded.

● Maintain purged enclosures to assure safe operations.

___________________________________________________________________________________________________________________________________________________________________________

Q. Can RAM be operated remotely?

A. Yes!

Remote operational capabilities are available and functional at a range of up to 2.5 miles.

___________________________________________________________________________________________________________________________________________________________________________

Q. Are RAM systems loud?

A. No!

RAM systems are acoustically sealed, insulated, and designed to typically be no louder than 70 decibels.

- Some exceptions may exist with select remote operated units.

___________________________________________________________________________________________________________________________________________________________________________

Q. Are RAM systems safe to operate?

A. Yes!

Due to its inherent safety features, the product’s Safety Record is unblemished and has not resulted in any reported personal injuries or deaths.

___________________________________________________________________________________________________________________________________________________________________________

Q. Is there a long learning curve as it regards system operations?

A. No!

RAM systems are intuitive and consistent from lab to production.

● Operator training accompanies every purchase.

Resodyn Acoustic Mixers, Inc. offers a RAM 5 Certification Course and Certificate of Training.

● Regarding both operation and maintenance of its production capacity mixers.

___________________________________________________________________________________________________________________________________________________________________________

Q. Is the equipment difficult to clean & maintain?

A. No!

RAM batch processing systems are bladeless and self-contained within a closed mixing vessel.

● Prevents batch cross-contamination.

● Provides ease of cleanup.

Resodyn’s Continuous Acoustic Mixer employs a Clean-In-Place (CIP) process which efficiently cleans the system.

● Reduces Waste.

● Minimizes or possibly eliminates operator exposure to harmful cleaning agents.

___________________________________________________________________________________________________________________________________________________________________________

Q. Is RAM Environmentally Friendly?

A. Yes!

RAM provides:

● Drastically reduced mixing and processing times.

-10-100X faster than conventional mixing equipment.

- Results in process step reduction supporting reduced energy consumption.

● Mixing proficiency.

- Drastically reduced material waste.

- Eliminate the need for solvents/chemicals for various mixing processes.

● Minimizes or possibly eliminates operator exposure to harmful cleaning agents!

___________________________________________________________________________________________________________________________________________________________________________