Changing the Game for Inhalation Powder Production

The following article is a result of a conversation with an international with operations in Europe and North America who wishes to remain anonymous.

The following article is a result of a conversation with an international with operations in Europe and North America who wishes to remain anonymous.

Inhalation powders have been the focus of recent environmental studies in the EU, showing that “between 2011 and 2021, the carbon footprint of pMDI-based inhalation therapy increased from 3,368 to 3,891 kilotons (kt) CO2 equivalents (CO2e).” This came about due to “a 16% increase in the number of sold doses of pMDI.” [1] The solution to this negative trend is a move to a different type of inhaler, known as a DPI or dry powder inhaler.

These inhalers do not rely on a propellant gas but instead have a complex formulation that uses larger excipient particles coated with finer API particles. The larger excipient is released into mouth by natural inhalation, and the finer API separates to enter deep into the lung. “As the powder is emitted from the inhaler, the drug particles separate from the carrier particles and are carried deep into the lungs, while the larger carrier particles end up in the oropharynx and are swallowed/cleared.” [2]

The challenge, for DPI formulations, comes when a higher percentage of API is needed. This happens for two primary reasons: the API supply changes to be increasingly available in lower potency, or when a higher dose is needed for the patient. Both scenarios require a higher API percentage in the formulation. Traditional mixing methods have been unable to achieve homogeneity at a higher dose.

Before Using RAM

Our customer, a large pharmaceutical company with operations throughout Europe and North America, shared some statistics about their mix quality. They have been using two types of mixing: a high shear blender and a low shear 3D tumble blender. The API powder is cohesive and fine, with particles smaller than 5 µm, while the excipient is a larger lactose particle around 200 µm. The important targets are an RSD of 3% or less and 25% API dose.

Both mixers were under performing on RSD and API %. The high shear blender worked quickly, but caused high attrition, affecting the content uniformity. The low shear tumble blender had low attrition and good content uniformity but took much longer and required much more intervention with multiple mixing steps due to the cohesive API powder.

Aerosolization in both mixing methods was the same, meaning they got the available API to the lungs. The focus, for the customer, was on optimizing the mix parameters for faster, higher quality processing with higher API %.

With RAM

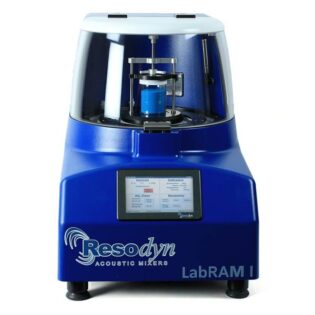

Our customer decided to test ResonantAcoustic® Mixing (RAM) because of a host of studies that demonstrate strong performance. They quickly noticed that mix speed, homogeneity, and API % were all improved to meet or exceed expectations.

| High Shear | 3D Tumbler | RAM | |

| Shear/Attrition | High | Low | Low |

| Content Uniformity | Unacceptable | On target | On target |

| RSD | >5% | >5% | <3% |

| Max API % | 15% | 15% | 25% |

| Mixing Recipe Steps | Single step | Many steps | Single step |

Application of RAM technology solved each issue, while maintaining aerosolization, giving our customer a much better and repeatable result prepared for higher API dosage requirements and facilitating their continued manufacturing despite supply changes to API potency.

Optimized Inhalation Powder Mixing

These processing improvements proved that RAM technology is ideal for creating homogeneous fine powder blends quickly and repeatably. The universal processing platform is ideally suited for mixing, coating, milling, and even sieving applications, all common processes in pharmaceutical production. Equally important, RAM equipment is available at multiple capacities, scaling seamlessly from the lab to high-capacity production.

Options include batch mixing in sealed containers, complete with robotic automation for semi-continuous production, and fully continuous mixing in our innovative continuous flow mixing system.

This scalability is crucial for pharmaceutical production because it essentially guarantees that what is working in the lab will work in the same way on the production floor, without significant reformulation or mix recipe adjustments. RAM technology is seamlessly scalable from bench through industrial batch and into continuous mixing. No other mixing platform has this capability.

Inhalation powders for DPI inhalers is an important growing trend. RAM technology is perfectly suited for producing these dry powders at the high standard required for safe manufacture, distribution, and delivery of important medicines.

CITATIONS

- Vartiainen V, Janson C, Hisinger-Mölkänen H, Lehtimäki L, Wilkinson A. Trends in inhaler use and associated carbon footprint: a sales data-based study in Europe. BMJ Open Respir Res. 2025 Sep 1;12(1):e002424. doi: 10.1136/bmjresp-2024-002424. PMID: 40889995; PMCID: PMC12406821.

- Levy ML, Carroll W, Izquierdo Alonso JL, Keller C, Lavorini F, Lehtimäki L. Understanding Dry Powder Inhalers: Key Technical and Patient Preference Attributes. Adv Ther. 2019 Oct;36(10):2547-2557. doi: 10.1007/s12325-019-01066-6. Epub 2019 Sep 2. PMID: 31478131; PMCID: PMC6822825.