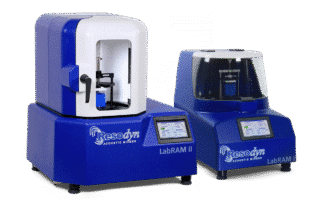

Why Resonant Acoustic Mixer's LabRAM Is the #1 Benchtop Lab Mixer for Modern R&D Facilities

In research and development, consistency, repeatability, and speed are non-negotiable. Whether you're formulating pharmaceuticals, developing new materials, or testing chemical blends, the mixing process at the benchtop scale must deliver both precision and repeatability. Traditional benchtop laboratory mixers—such as overhead stirrers or magnetic mixers—have served laboratories for decades, but they come with limitations in efficiency, scalability, and compatibility with complex materials.

Enter Resonant Acoustic Mixing (RAM)—a disruptive benchtop lab mixing technology that uses low-frequency, high-intensity acoustic energy to mix materials without blades or impellers. Originally developed for advanced aerospace and defense applications, RAM has rapidly gained traction in commercial laboratories of all types for its MANY unique benefits.

How Resonant Acoustic Mixing Works

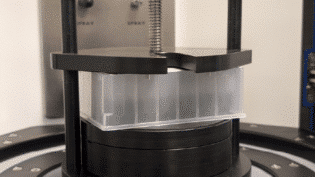

RAM uses acoustic resonance to generate uniform energy throughout the entire volume of the mixing vessel. This energy is transferred directly into the materials, regardless of their viscosity or phase (liquid, solid, powder, gel, etc.). The result is a thorough, reproducible mix—without the need for rotating blades, shafts, or manual intervention.

Why RAM is the Ideal Benchtop Mixer

1. No Cleaning, No Cross-Contamination

Because RAM mixes materials directly inside sealed containers (such as vials, syringes, or jars), there’s no cleaning between batches and no risk of cross-contamination—a huge advantage in regulated or high-throughput labs.

2. Handles Difficult and Sensitive Materials

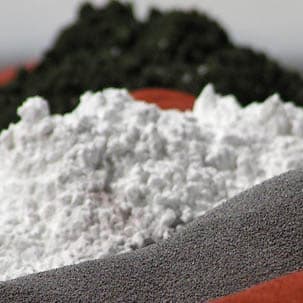

Traditional benchtop mixers struggle with high-viscosity materials, powders, or immiscible systems. RAM excels with:

- High-viscosity adhesives or creams

- Dry powder blends (even with large particle size differences)

- Thermally sensitive or shear-sensitive compounds

- Fragile components like biological agents or microspheres

3. Repeatable, Scalable Results

RAM ensures uniform energy distribution, producing highly reproducible results—crucial for R&D and validation studies. And because the same technology scales up to production units, you can go from benchtop to manufacturing without re-optimizing the mixing process.

4. Fast, Energy-Efficient and Time-Saving

Mixing times are significantly reduced, often by 10x or more compared to conventional methods. Since mixing happens in closed containers, there's also no need for nitrogen blankets, extra containment, or inert environments in many cases.

5. Compact, Clean, and Quiet

Benchtop RAM devices are fully enclosed, compact, and electronically controlled, making them well-suited for laboratory environments where space and cleanliness are at a premium. They also operate more quietly than traditional mechanical mixers.

Use Cases Across Industries

- Pharmaceuticals: Blending APIs with excipients, mixing powders, gels or compounding personalized medicine

- Materials Science: Creating uniform nanomaterial suspensions or battery slurries

- Cosmetics: Emulsifying lotions without overheating or shear damage

- Aerospace & Electronics: Mixing reactive epoxies or solder pastes with long pot lives

- Energetics: The industry most familiar with acoustic mixing and that has seen amazing leaps forward in the processing of pyrotechnics and energetic materials.

The Future of Benchtop Laboratory Mixing Is Resonant

In the world of benchtop mixers, resonant acoustic mixing isn’t just a new option—it’s a paradigm shift. Its contactless, container-based approach eliminates the traditional tradeoffs between mixing performance, cleanliness, and scalability.

For research and development labs that value speed, reproducibility, and simplicity, RAM delivers a uniquely powerful and flexible solution—without the mechanical headaches.