NASA Creates New Super Alloy GRX 810 Which Withstands Temperatures Exceeding 2000 Degrees Fahrenheit and Lasts up to 2500x Longer than Traditional Alloys with a Resodyn Acoustic Mixer!

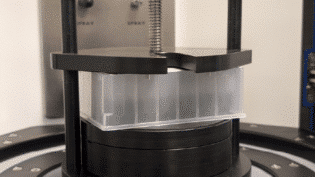

NASA utilized RAM technology to develop GRX-810, a groundbreaking oxide dispersion-strengthened (ODS) superalloy. By coating NiCoCr metal alloy powder with nanoscale Y₂O₃ oxide particles using RAM, they achieved a material capable of withstanding temperatures exceeding 2000°F and exhibiting up to 2500 times the durability of traditional alloys. This uniform, non-deforming coating process was unattainable with conventional mixing methods, which often led to particle deformation and poor flow characteristics

GRX-810 can be used in space launch systems, heat exchangers in nuclear power plants and other extreme temperature environments, thanks to Resonant Acoustic Mixing (RAM) technology.

Download the case study here <---

Powder metal products are used across a spectrum of industries such as aerospace, automotive, marine, and biomedical. Other common products created with powder metals include engine components, auto brake shoes/pads, medical devices, and bearings impregnated with lubricants.

Powder metals are also used in heat shields for spacecraft, high-voltage electrical contacts, and filters for gases. Parts created from powder metallurgy are often used as additive manufactured prototypes as well as fully functional components.

In conlusion: NASA uses RAM to coat Nickel Cobalt Chrome with Yttrium Oxide powder to create GRX 810. GRX-810 withstands temperatures exceeding 2000 ⁰F, and lasts up to 2500 times longer than traditional alloys.

GRX-810 is expected to make billions of dollars.

Check out the video to hear the full story!

“... Acoustic mixing opens up the possibility of adding oxides or ceramics to any metal, which creates a huge design space that wasn’t previously available...”

- Materials Engineer U.S. Government Research Organization

“We tried mechanical alloying, but ball-milling destroyed the morphology of the powder. What was spherical and able to flow in the 3D printer became deformed, platelet-like and had a tendency to stick in the 3D printer. Instead, we coat the metal powder with ceramic oxide using Acoustic Mixing and get a really nice, dense coating on all the powder that doesn’t deform the powder, or affect the flow through the 3D printer.”

- NASA Materials Engineer TM Smith, et al

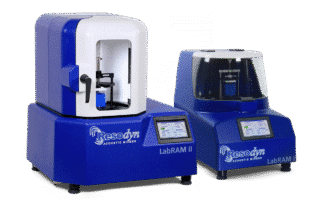

“...[we] mix different rheologies with powder metals, highly viscous, and the LabRAM II has proven it can do that effectively. We’re very impressed with the build quality of the mixer--it’s a nice, solid, well-thought-out piece of equipment. It’s done very well for us...”

- Research Scientist U.S. Government Agency