You’ve carefully selected your materials, meticulously designed the mixing plan, yet the technology used is not up to the task.

Mixing technology is often overlooked in the product development equation. Repeated test iterations produce marginally improved, or insufficient results. Existing mixing technology often needs some fixing of its own.

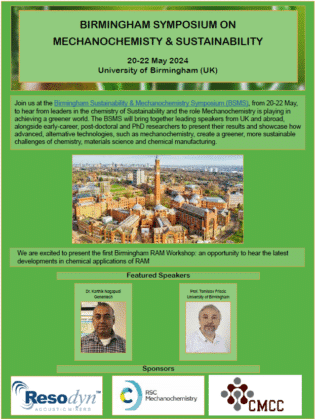

ResonantAcoustic® Mixing (RAM) technology is available today that delivers your mix plan’s results as expected:

- High quality product - by any metric

- Rapid and thorough mixing

- Consistent, repeatable results

- Minimal clean-up and waste materials

- Elimination of failed batches and lost ingredients

Discovering the right solution

Even when working properly and well-maintained, your mixing technology may not be capable of getting your mix right. For many liquid and paste mixing applications, intrusive, engineered blades/impellers in the mixing vessel characterize traditional technologies. These spinning devices create vortices to mix but mix only locally at the tips of the blades/impellers.

All remaining material must be transported from various location in the mix vessel to the vortices to be processed. RAM eliminates inefficient transport and the lengthy processing times created by conventional mixing technologies.

For powder mixing, tumbling devices are common, routinely characterized by long mix times and incomplete mixing. RAM technology combines rapid vibrations and acoustic energy to create a chaotic mixing field in the powder material matrix to speed processing and dramatically improve results.

All in

RAM technology engages all material in the mix vessel- instantly and continuously. The result is rapid, uniform, repeatable mix results in a fraction of the time required by conventional mixing technologies, consistently producing high-quality products.

How to get it right

Learn how RAM can be an essential tool to solve your mixing issues from powders to pastes, laboratory to production, and across virtually any material application.