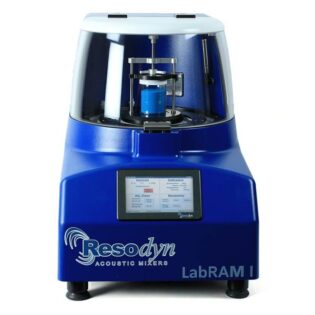

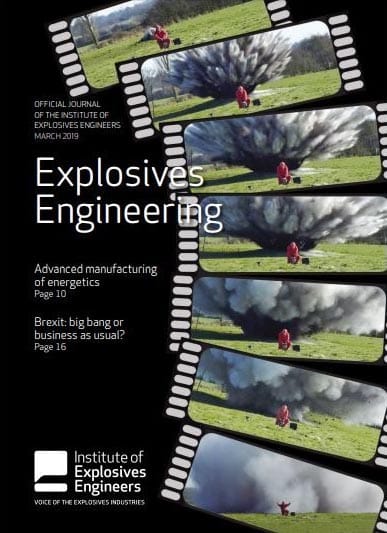

ResonantAcoustic® Mixing (RAM) is highlighted as a key technology component in the future of energetic material production in an article entitled Advanced manufacturing of energetics: previous experiences and new opportunities in the 2019 Journal of the Institute of Explosives Engineering.

The article explores challenges and dangers associated with traditional methods of energetics manufacture, and how the latest technologies promise to make big improvements.

RAM’s speed, safety, and mix quality are discussed as primary advantages over traditional processing methods. Resodyn’s Continuous Acoustic Mixing (CAM) and Continuous Acoustic Reactor (CAR) technologies are also highlighted, promising to further revolutionize energetics production. The article concludes that RAM, 3D Printing, and Flow Reaction/Chemistry have combined potential to make “the energetics factory of the future” more efficient, more versatile, and safer.

The journal is available to members of the Institute of Explosives Engineering on their website.

The article's author, Jim Fleming has more than 35 years’ experience with energetic materials and systems at organizations including the UK Ministry of Defense and Roxel (UK Rocket Motors) Limited. His career has included energetics facility Process Safety and New Product Development, spanning many roles from operations to business development, and recently included a position on Roxel UK’s Senior Management Team.

Fleming has a BSc in Chemical Engineering and an MSc in Engineering Business Management. He is a Chartered Engineer. Today, he provides independent consultancy as Director of FCIT2 Limited.