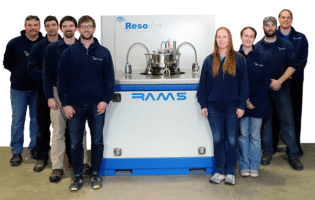

ResonantAcoustic® Mixing for Energetics: At the Heart of Purdue Energetics Research Center Grant

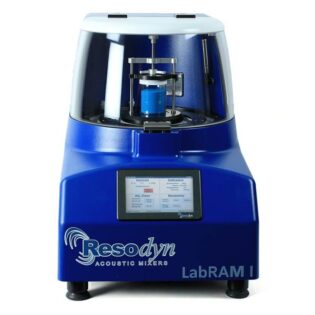

The Purdue Energetics Research Center (PERC) has announced $7 million in U.S. Department of Defense funding to modernize energetics manufacturing, accelerating the move from batch processes to continuous production. The centerpiece of the program is ResonantAcoustic® Mixing (RAM) technology, using our advanced continuous acoustic mixer configurations. This validates what our customers already know: RAM is the most advanced, research-backed, and production‑proven way to safely process high‑viscosity energetic formulations at unmatched speed and homogeneity. It's the ultimate mixer for energetics.

Why Resonant Acoustic Mixing is the Energetics Industry Benchmark:

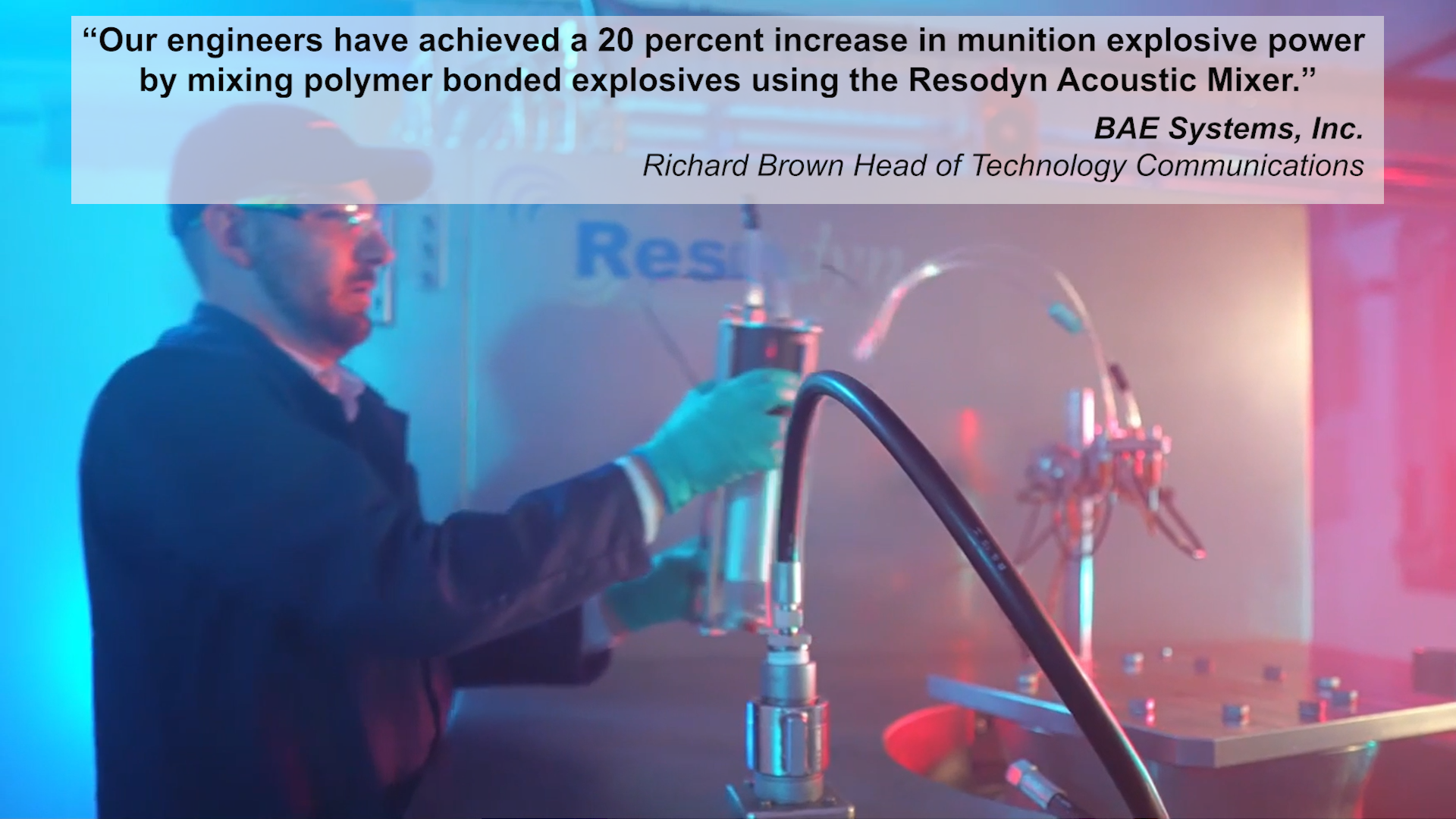

- Outperforms conventional mixers on high‑viscosity energetics: RAM applies uniform acoustic energy throughout the mixture, achieving rapid, consistent results where blade and impeller systems fail.

- Unmatched speed & homogeneity: RAM delivers fast, repeatable dispersion with superior homogeneity, safely mixing materials in minutes, not hours.

- Safer, bladeless energy transfer: Minimal mechanical contact supports safer handling of sensitive materials compared with traditional batch blade mixers.

- Continuous‑production ready: Several RAM models are fully capable of continuous production for increased efficiency and higher throughput.

- Waste reduction by design: Fewer out‑of‑tolerance batches, and tighter process control mean less scrap and lower disposal burden are key wins for cost, safety, and sustainability.

- 100% effective Clean‑In‑Place (CIP) on continuous mixers: Our continuous RAM systems feature complete CIP coverage to cut solvent use, shorten changeovers, and maintain validated cleanliness.

Resodyn is proud to be a key part of modernizing energetics production for enhanced quality, throughput, and safety. Check out the Purdue Energetics Research Center and their important work by following the link below.

Read the Purdue news release: Purdue Energetics Research Center aims to modernize manufacturing of energetic materials

See RAM Mixers for Energetics in action on your formulation.

👉 Request a live demo

Frequently Asked Questions (Energetics & RAM)

Q1: What makes ResonantAcoustic® Mixing different from blade or impeller mixers?

A: RAM uses acoustic energy to move the entire mass of material in a controlled field, producing rapid, uniform mixing without blades. This approach is especially effective on high‑viscosity, sensitive energetic formulations, where conventional impellers face torque limits, dead zones, and longer mix times. [Purdue Ene...ing of ...]

Q2: Can RAM support continuous and semicontinuous production of energetics?

A: Yes. RAM integrates into continuous and semicontinuous manufacturing architectures with inline monitoring and advanced control—key elements highlighted in Purdue’s modernization program.

Q3: How does RAM improve safety for energetic materials?

A: RAM’s bladeless energy transfer reduces friction points and mechanical contact compared with traditional batch blade mixers, while enabling shorter cycles and real‑time control that help avoid off‑spec product and the risks associated with rework and disposal.

Q4: What about waste reduction and environmental impact?

A: Faster attainment of target specs and consistent homogeneity translate directly into less scrap and fewer off‑spec batches. In continuous lines, RAM’s 100% effective CIP further reduces solvent use and turnaround time, cutting both costs and environmental load.

Q5: How uniform is the final product compared with traditional methods?

A: RAM is engineered for exceptional homogeneity, even at high viscosities, delivering tight lot‑to‑lot consistency that supports stringent performance requirements in explosives, propellants, and pyrotechnics.

Q6: Is there independent validation of acoustic/bladeless mixing in this space?

A: Purdue’s PERC program—funded by the DoD—explicitly identifies bladeless mixing driven by acoustics and notes implementation through a train of mixers developed by Resodyn as part of its modernization strategy.

Q7: Where is Resodyn based, and can you support U.S. government programs?

A: Resodyn is headquartered in Butte, Montana, with extensive experience supporting U.S. defense and industrial customers with RAM technology for sensitive, high‑viscosity materials.