The Benefits of ResonantAcoustic® Mixing (RAM) in Pharmaceutical Blending

In pharmaceutical blending and manufacturing, consistency, speed, and reliability are critical to ensuring product quality and patient safety. Traditional blending methods—such as V-blenders, ribbon blenders, and high-shear mixers—often face challenges when handling fine powders, highly potent APIs, or multi-component formulations. ResonantAcoustic® Mixing (RAM) technology is emerging as a transformative alternative, offering pharmaceutical companies a highly efficient, scalable, and repeatable blending solution.

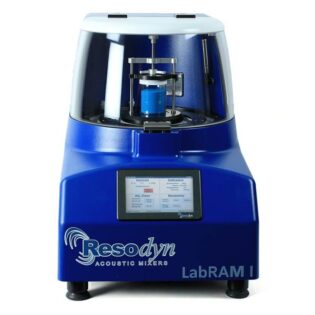

What is ResonantAcoustic Mixing?

RAM technology uses low-frequency, high-intensity acoustic energy to agitate materials uniformly throughout the mixing vessel. Unlike conventional impeller or blade-based mixers, RAM achieves mixing without contact, relying instead on acoustic resonance to create a rapid and uniform distribution of particles, powders, or liquids. This unique mechanism eliminates many limitations of mechanical blending while delivering superior process control.

Key Benefits of RAM for Pharmaceutical Blending

- Superior Blend Uniformity

Meeting and exceeding content uniformity requirements is one of the most pressing challenges in pharmaceutical blending. RAM provides exceptionally homogeneous mixing—even for formulations with trace-level APIs or excipients. Independent studies and customer experiences consistently report lower standard deviations in blend uniformity compared to conventional mixers.

- Scalability Without Re-Validation Challenges

One of RAM’s most significant advantages is linear scalability. Whether blending milligram-scale R&D batches or kilogram-scale production runs, the same mixing principles apply. This reduces the need for costly process re-validation, accelerating development timelines and facilitating smoother tech transfer from lab to production.

- Reduced Processing Time

RAM’s efficient energy transfer dramatically reduces blend times. In many cases, processes that traditionally take 30–60 minutes can be completed in just a few minutes. This reduction not only improves throughput but also lowers operating costs and enhances overall productivity.

- Non-Destructive Mixing

Unlike high-shear mixers, RAM does not rely on blades or impellers, eliminating the risk of particle damage or changes in crystal morphology. This makes it particularly valuable for sensitive formulations, such as biologics, amorphous dispersions, and inhalation products, where maintaining particle integrity is essential. RAM is the top choice for a low shear mixer.

- Closed, Contained, and Safe Processing

Pharmaceutical manufacturing often involves handling potent or hazardous materials. RAM systems use sealed vessels that minimize operator exposure and reduce contamination risk. This closed-system design aligns with stringent GMP requirements and improves overall workplace safety.

- Versatility Across Dosage Forms

RAM has been successfully applied to a wide range of pharmaceutical products, including:

- Solid oral dosage forms (powder blends, direct compression tablets)

- Inhalation products (DPI blends with highly potent APIs)

- Injectable suspensions and biologics

- Controlled-release formulations

This versatility allows manufacturers to consolidate blending technologies into a single, flexible platform.

7. In pharmaceutical blending, various ingredients are used depending on the formulation and intended use. Common ingredients include:

- Active Pharmaceutical Ingredients (APIs): The primary ingredients that provide therapeutic effects.

- Excipients: Inactive substances that serve as carriers for the API. They can include:

- Fillers: Such as lactose, microcrystalline cellulose, or starch, which add bulk.

- Binders: Like polyvinylpyrrolidone (PVP) or hydroxypropyl methylcellulose (HPMC), which help hold the mixture together.

- Disintegrants: Such as croscarmellose sodium or sodium starch glycolate, which promote the breakdown of the tablet.

- Lubricants: Such as magnesium stearate or stearic acid, which prevent ingredients from sticking to equipment.

- Glidants: Such as talc or colloidal silicon dioxide, which improve powder flow properties.

- Coatings: For tablets, these may include film-forming agents like HPMC or enteric coatings that prevent dissolution in the stomach.

- Preservatives: To prevent microbial growth in liquid formulations, common preservatives include parabens or benzalkonium chloride.

- Stabilizers: To enhance the stability of the formulation, such as ascorbic acid or citric acid.

The specific choice of ingredients depends on the desired properties of the final product, such as bioavailability, stability, and release characteristics.

PharmaRAM Mixers Do It All in the World of Pharmaceutical Blending

But it is now easy-and there is no issue with scale of pharmaceutical product blending. Bench, pilot, or production volumes all mix the same when using the ResonantAcoustic® Mixing system from Resodyn Acoustic Mixers.

ResonantAcoustic® Mixing works with quality and speed:

- Seamless scaling from bench to pilot to production through continuous blending

- Non-contact blending – no blades are used

- Multiple combinations of powder types and semisolids

- Deagglomerates API aggregates without changing crystal habit

- Thorough homogenization for every blend

- Achieves RSD values as low as <1%

- One blender for all powder blending challenges

- Perfect blend -no over blending or un-mixing

- No cross-contamination

- 10x to 100x times faster than conventional blenders -reduce blending times from hours to minutes or even seconds

ResonantAcoustic Mixing is redefining pharmaceutical blending by delivering faster, cleaner, and more consistent results across all stages of development and production. By reducing blend times, improving uniformity, and providing a scalable, closed-system process, RAM technology empowers pharmaceutical companies to meet quality standards more efficiently while lowering operational costs.

As the industry continues to push for innovation, efficiency, and patient safety, RAM stands out as a powerful technology for the future of pharmaceutical blending.

Selecting the right pharmaceutical blender design for the final product used to be a difficult decision because of the various ingredients and mixers needed.

The best companies have moved away from legacy pharmaceutical blender designs like ribbon, paddle, conical screw, or tumble. Instead they invest in tomorrow’s technology that's here today.