Rapid R&D: High Throughput Discovery that Scales

In every industry that develops materials for an end market, research and development is a critical part of the roadmap. Examples include:

- pharmaceutical, which invests heavily in many failed experiments before finding successful formulations;

- batteries, where challenging chemistries hold the key to significant increases in energy density, stability, and cost;

- defense, where production is dangerous, slow, and super critical for preserving national sovereignty;

- and additive manufacturing, which has seen major investment in exploring where 3D printing technology is best applied.

In each of these cases, and many more, the time spent on R&D is a driving factor of both cost and risk. Minimizing the time to successful lab results is a big and worthy goal of any Director of R&D or Lab Manager. Thankfully, there are tools that help; ResonantAcoustic® Mixing (RAM) is one of them.

Here are several important ways that RAM speeds up R&D and reduces risk for scale up:

Ultra-Fast, Uniform Mixing

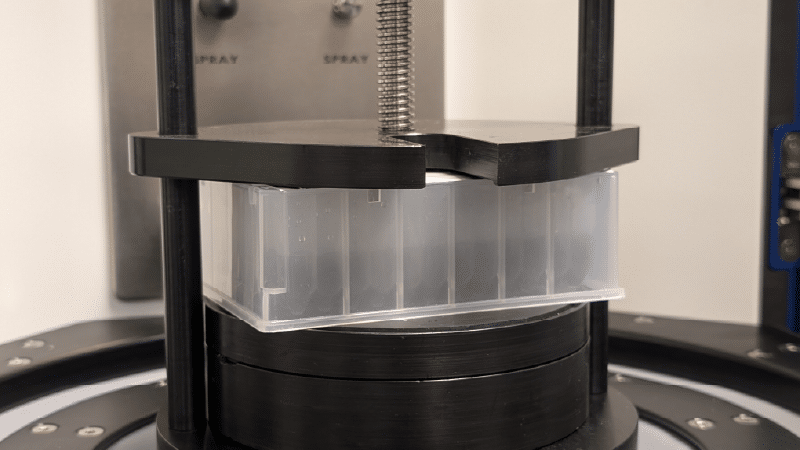

Resonance is an incredibly powerful force. Harnessing it for mixing materials is a huge advancement. Unlike bladed mixers, ResonantAcoustic® processing is extremely efficient, evenly distributing mixing energy throughout the entire vessel and achieving excellent uniformity very quickly. Many processes are done 10x faster. Some are even 100x faster.

And we mean done. The level of uniformity is often unattainable by any other means. RAM doesn’t just speed up the mix time; it also ensures that every mix is high quality, so no repeats are needed. Confidence in the result soars as well, giving lab technicians a very high assurance that the job was done both quickly and well.

This saves an incredible amount of time and money that would have been previously wasted on poor results, overly burdensome QA validation, and a lot of head scratching.

Gentle, Low Shear Particle Preservation

Other high-speed mixers tend to create a lot of shear force and heat. This is very damaging to many particles that need to be preserved for the blend to be safe and effective. Resonant processing spreads the energy out to the whole vessel, as mentioned above, reducing hot spots and nearly eliminating shear.

In the R&D world, this means an important gain in experiment efficiency. Less scrap, more quality. It is also much safer when particles are shear or heat reactive.

All-in-One Technology

Perhaps the most underrated benefit of using RAM in a lab (and on the production floor for that matter) is the versatility of the machine. It can mix extremely well, but it can also coat, mill, and sieve. RAM is a popular alternative to ball milling, for example. It’s used often to coat larger particles with smaller ones. And some even use RAM to process material through a sieve.

RAM can process any material, be it powders, liquids, slurries, or pastes. In fact, RAM is used when the parameters are especially difficult, such as high viscosity, challenging morphology, liquid immiscibility, heat sensitivity, and so on.

Normally, multiple machines would be needed to cover a variety of scenarios. With ResonantAcoustic® processing, this need is reduced or eliminated, saving valuable time and real money.

RAM Mixes Small

Resonance works the same at both the micro and macro scales. This is critical for scaling up and down. In R&D, where experimentation is rapid and tests often go in the trash, using less material to find successful results is important. In the pharmaceutical industry, mixing small is incredibly important as the Active Pharmaceutical Ingredients (APIs) are very expensive. Using as little as possible is a major cost savings, maintaining the ROI of the costly drug development process.

RAM has successfully mixed a few micro grams of materials at a time and even coated small beads with a nanomole quantity of reagent. The ability to mix small quantities with confidence that it can also mix large amounts is paramount.

Lab Specific Attachments

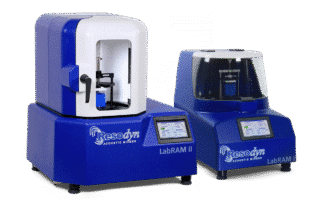

Mixing equipment at the production scale often comes with a variety of additional equipment to control temperature, pressure, gases, etc. Our LabRAM II model can be configured with these options scaled for the lab environment. This means full experimental control, safer operating conditions, and higher quality results.

Scaling to Production is Seamless

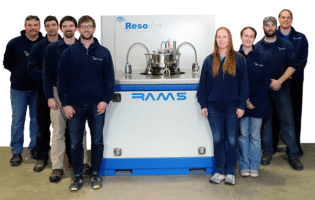

RAM can scale up because the operating principle works exactly the same at production capacity. Our tests have shown that scaling from lab to production requires very little recipe adjustment, if any, for the same homogeneity, speed, and material characteristics. Our larger production models may look different and have more advanced control features; however, they are functionally very similar to our lab machines.

This means scaling up is completely seamless in almost every case. When adjustments to the mix recipe are needed, our engineers can help identify those and fine tune production with ease. For R&D teams specifically, this means less risk and greater confidence that lab work will translate to efficient production.

Smarter R&D with RAM

ResonantAcoustic® processing is an R&D lab’s secret tool to faster, better mixing, coating, milling, and sieving. There is no better tool for high quality results in nearly any situation and with nearly any material. Check out our innovative mixer lineup here.

We’d like to discuss your material processing challenges. Let our expertise compliment yours as we work together to solve your next R&D challenge. Contact us today for a free consultation and we can schedule a demonstration, line up a mix test, and discuss your discovery options to help you prove the technology.