The Critical Role of Mixing in Powder

Quality and Performance

The Hidden Failure Mode in Materials Science

Mixing is an often overlooked but critical step in both R&D labs and on the production floor. Most teams undervalue blend uniformity and as a result, experience avoidable difficulty and failure. Instead of treating mixing as a routine prep step, more scientists and engineers need to understand that it’s a determinant of performance.

Unfortunately, underinvestment in mixing equipment matches the often-cavalier attitude towards mixing. This leads to a host of problems from no positive outcomes to intermittent, unreliable successes. Poor mixing is the silent root cause behind more failed experiments and off-spec products than most teams admit.

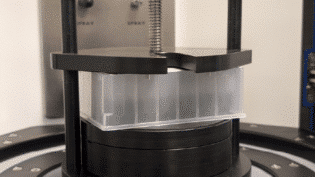

The secret to ResonantAcoustic® Mixing is that it drives complete and thorough mixing through the power of resonance. While there are several mixing technologies and a host of equipment providers, many are insufficient for the application, leading to mixing challenges the world over.

Across industries, from energy storage to pharmaceuticals, the story repeats: blend uniformity equals reliability. To understand why, let’s take a look at what is really happening within the mix.

How Mixing Fails — and Why It’s So Hard to See

Mixing failure happens for many reasons. From improper equipment (more on this later) to particle morphology, de-mixing or segregation is a common problem. One of the challenges with segregation is that you often cannot see it without the appropriate analytical equipment, used at the right time in the development and production process.

De-mixing is caused by a variety of phenomena that drive materials apart. In powders, de-mixing is typically a direct result of the particles’ morphology; that is the size, shape, density, or surface texture of the particles which are being mixed. These properties will impact if particles will flow or clump, settle or rise, relative to each other.

De-mixing caused by small differences can, and does, turn a good formulation into an off-spec product [1]. What looks like a uniform blend can hide pockets of unmixed material that only show up in test results. The key is to identify the right mixing technology and build processes to match, testing often throughout both mixing and material handling stages, in the lab and during production. Ensure a thorough blend to begin with and optimize handling to eliminate segregation.

Why Powder Blend Uniformity Determines Performance

Mixer type and the associated mix process parameters are directly linked to final content uniformity; choosing the proper powder mixing technology is a decision which heavily impacts quality [2][5][6]. Without a completely homogeneous blend, the result will be inefficient, intermittent, or entirely ineffective.

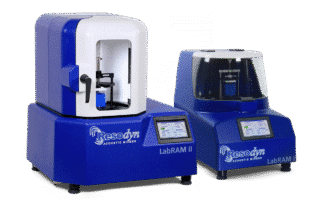

This is where Resodyn Acoustic Mixers really shine: industry best homogeneity, every time, at breakneck speed. This enables the ideal chemical reactions, the best curing, the right dosing, and optimal material properties in everything from powdered metals to pharmaceutical formulations.

Without proper uniformity, you don’t get the desired outcome. With inconsistent dispersion comes inconsistent results.

The Quality Imperative — Mix Uniformity as a Critical Attribute

Blend uniformity is now formally recognized as a Critical Quality Attribute (CQA) in many regulated industries. That’s because these industries realize what we should all know: tomorrow’s material breakthroughs depend as much on how they’re mixed as on what they’re made of.

Industry leaders treat quality metrics like homogeneity, blend uniformity (BU), content uniformity (CU), composition variance, and relative standard deviation (RSD) as CQAs — measurable, reportable, and non-negotiable. This is not a trend, but a scientific approach to materials advancement. Poor mixing leads to bad results, or no results at all, wasting both time and money on experimentation that was destined to fail. On the other hand, high-quality, reproducible mixing saves time, improves data, and prevents costly reformulation.

RAM is a proven pathway toward that consistency [8].

If you haven’t looked at your mixing as a quality driver, instead of a routine prep, start there. The best materials science starts with the best mixing. Contact us for a free consultation and we can explore ResonantAcoustic® Mixing for your application. We have many ways for you to prove RAM, including mix texts and rental units, so you can discover for yourself if we can push your material to the next level.

References

- Jakubowska E., Blend Segregation in Tablet Manufacturing and Its Effect…

- Versaci D. et al., A comprehensive study on LNMO/LFP blending… Journal of Power Sources (2024).

- Osorio J.G. et al., Evaluation of Resonant Acoustic Mixing Performance (LabRAM study, 2015).

- Jaspers M. et al., Batch versus continuous blending of binary and ternary mixtures (2022).

- Buyukgoz G.G., Impact of Mixing on Content Uniformity of Thin Polymer Films (MDPI, 2021).

- Alyami H. et al., Effects of excipient particle size on content uniformity (PLoS One, 2017).

- T. Smith, C. Kantzos, T. Gabb, NASA High Temperature Alloy Development GRX-810 (Nasa.gov, 2023).

- Resodyn Technical Folios (Battery, Energetic, and Pharma Applications).