In recent years many companies have been seeking innovative solutions to improve the sustainability of their manufacturing processes and products. Sustainable manufacturing is defined by the U.S. EPA as “the creation of manufactured products through economically-sound processes that minimize negative environmental impacts while conserving energy and natural resources. Sustainable manufacturing also enhances employee, community and product safety.” There are many benefits to pursing sustainable operations including waste reduction, efficiency gains, improved brand reputation, and compliance with new regulations – all of which can improve competitiveness.

When it comes to industrial mixing equipment, there are many options to choose from. Not all mixing technologies, however, are environmentally friendly or offer opportunities for sustainable manufacturing. One industrial mixing technology that is able to minimize environmental impact is ResonantAcoustic® Mixing (RAM) from Resodyn Acoustic Mixers.

What is RAM?

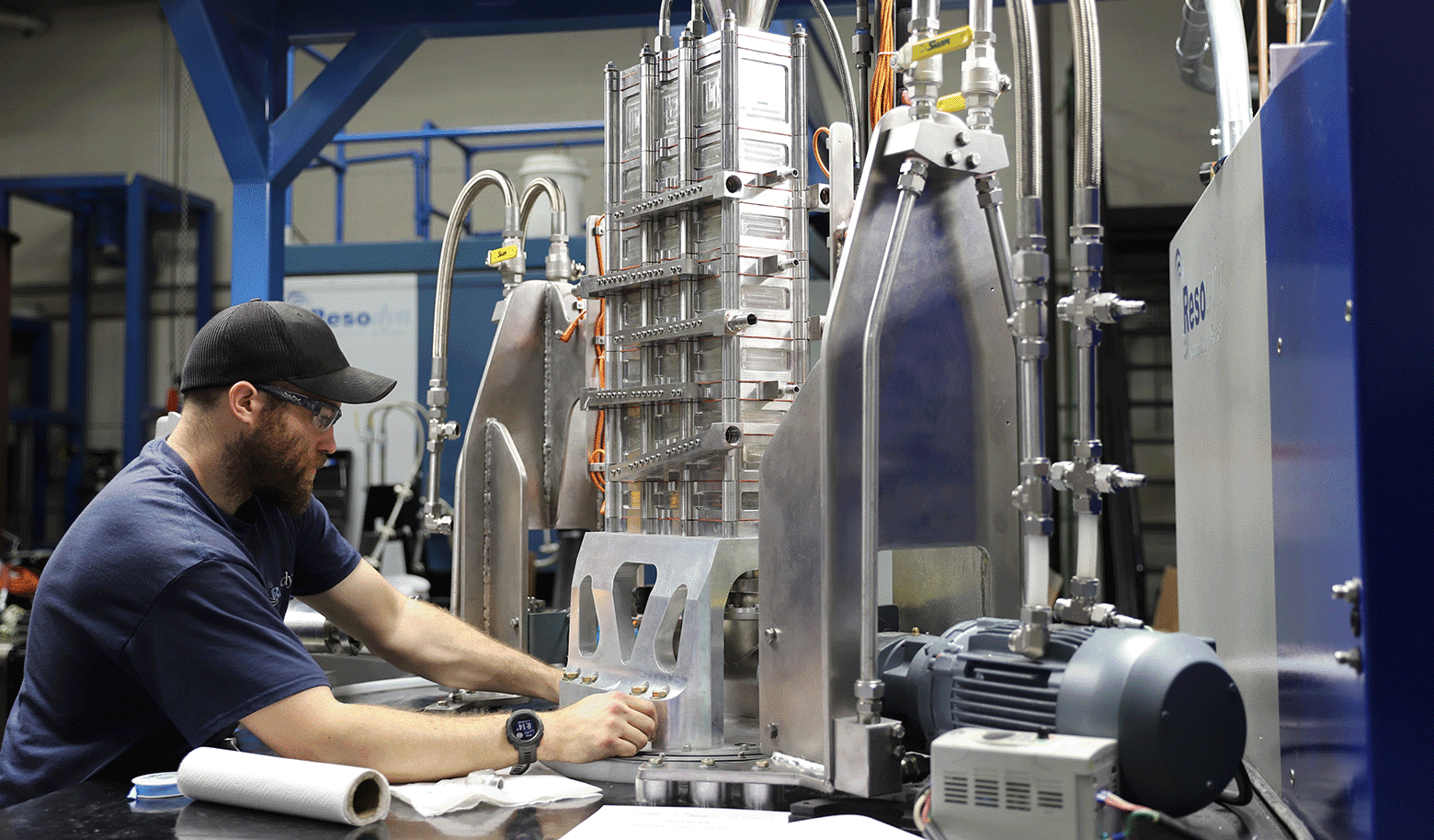

RAM technology employs low-frequency energy to generate unique material movement and sound-induced (acoustic) interaction within a mixing vessel. It does so without the use of an impeller or other traditional mechanical mixing implements. Acoustic energy is generated by the vertical motion of RAM’s resonator plate or mixing platform and attached vessel holder. At 60 times per second, RAM technology creates both motion of the ingredients inside the vessel as well as acoustic (“sound”) energy. This energy emanates through a RAM mixer’s base during its upward motion, and is then repeated by the inside of the vessel’s lid during the downward motion (thus, both lid and base act as transducers).

The combined energy generated by motion and sound imparts a high level of energy, up to 100 times the force of gravity into the mixing ingredients, which causes the particles – in a powder mixing application - to continuously collide in a random, chaotic manner. This results in swift, continuously-efficient mixing as well as precise and uniform blending at macroscopic, microscopic, and even sub-micron levels. In liquid and viscous mixing applications, RAM technology generates highly active surface disturbances between the materials, greatly multiplying the interface area between them speeding and improving the mixing efficiency and quality.

How does RAM Minimize Environmental Impacts?

The RAM technology is not only known for its speed and efficiency, but its quality results as well. These factors allow RAM operations to be more environmentally friendly than most traditional mixing methods. Some of the ways RAM operations minimize the environmental impact of mixing include:

- Minimization of off-spec waste. RAM mixing is consistent and highly reproducible, resulting in predictably high quality, uniform products without the waste and costs associated with failed, off-spec batches. Additionally, when required for certain ingredients, RAM systems can incorporate specialized processing conditions. These include mixing under vacuum, or at a controlled temperature to create mixing conditions that minimize the potential for failed batches and waste generation.

- Minimization of cleanup waste. Most traditional mixers employ in-vessel agitators or other engineered internal devices that can be very difficult to clean. Any mixing material remaining on the internals after mixing typically becomes waste during the cleanup step, which generates a considerable amount of waste over time and other discarded cleaning materials. RAM mixing, on the other hand, does not have any internal components to clean. A single vessel without internal mechanical agitators enables easier and faster cleaning and maintenance with less waste generation during clean-up, regardless of the material being processed.

- Lower energy consumption. RAM mixers are extremely efficient. They dramatically reduce mix times versus traditional mixers (in many cases from hours to minutes). The comparatively inefficient mixing method of a traditional mechanical mixer typically requires much longer mixing times to achieve comparable uniformity to mixes performed by RAM. Such inefficiencies result in higher energy consumption and longer cycle times without achievement of the levels of quality or repeatability possible with RAM. Furthermore, as the viscosity of raw ingredients increases, mixing requires even more energy and time to blend motor-drive units, which only adds to high operational costs. RAM operations enable organizations to minimize environmental impact with comparatively low energy consumption and faster cycle times, even when mixing viscous materials. Further, the nature of the resonant mechanical condition enables RAM mixers to continue to operate at a high level of mixing energy with a minimum of additional energy input.

- Sustainable solutions for continuous operations. For companies that need continuous mixing operations, Resodyn’s Continuous Acoustic Mixer (CAM) system is an excellent option, especially when it comes to environmental considerations. CAM brings RAM technology to high-throughput industrial mixing applications. Each CAM system delivers an environmentally friendly Clean in Place (CIP) process that enables no-contact, no-disassembly cleaning. This substantially reduces both waste and labor required for cleanup vs. batch mode processing. Click here for more information about how the U.S. Department of Defense uses Resodyn’s CAM technology to minimize waste and improve safety during production of various explosives, rocket propellants, and pyrotechnic formulations for military use under its Strategic Environmental Research and Development Program (SERDP) program.

About Resodyn Acoustic Mixers Inc.

From the world's top international manufacturers, global tech giants, new material developers, and nearly every U.S. National Laboratory, public and private organizations in more than 30 countries rely on Resodyn Acoustic Mixers’ single, powerful RAM technology platform. Whether used for development of new products and processes in a laboratory or for running full-scale industrial production, RAM systems are available in configurations to fit industrial mixing applications across dozens of industries.

Resodyn is the only company in the world to offer RAM technology. Change the way you think about mixing and processing with a RAM demonstration: on-line or on-site at your facility, using your own materials, and solving your mixing challenges.

Need help with a challenging mix? There is no better way to understand the RAM difference than seeing the technology in action. RAM sales professionals deliver high value, on-site application presentations, product technology demonstrations, and even mixing tests using your own materials, without cost to you. Contact us today to discuss your requirements or to schedule a free, on-site, or live web demonstration.