Industrial mixing has evolved over time into a sophisticated and complex process. There are a multiude of mixers and integral accessories on the market, each combination typically focused on mixing a specific set of ingredients. While the range of mixing machines and attachments seems infinite, the number of mixing technologies available is finite. This article explores the top five types of mixing technologies in detail: ribbon, tumble, planetary, centrifugal, and ResonantAcoustic® Mixing (RAM).

Ribbon

This type of mixing technology has ribbons attached to the shaft. The ribbons are typically thin, sharp, corkscrew-shaped blades that rotate to break up the contents within a mixing vessel. The outer ribbon blades rotate in one direction while the inner blades rotate in the opposite direction, creating material movement within the mixer. Ribbon speeds are adjusted to achieve a desired mix result. This method is a good option for dry, free-flowing solids such as powders as well as liquid-solid combinations. An everyday example of this form of mixer is a food blender. Two of the main challenges for ribbon mixers are uniformity and attrition. The ribbon blades often damage the particles, especially when operating at higher speeds that generate high shear forces within the mixer. Additionally, the level of mixing varies within a container. It is greater nearest the blades, so a given mix is not consistent or uniform throughout the vessel. For this reason, ribbon mixers often need to be operated for a long period of time to achieve desired mixing uniformity and consistency. This in turn increases cycle times and operating costs.

Tumble

Tumbling mixers use diffusion to achieve the desired mixing. These mixers consist of a sealed mixing drum orvessel that blends and rotates at a given speed, using gravity to assist with material flow within the vessel. One key differentiator from other mixing methods is that tumblers do not have an agitator. For this reason, particle damage and particle size reduction are less of a risk with tumblers. One challenge for this technology, however, is segregation after mixing, or “overmixing.”. This makes tumble mixers most suitable for liquids and solids in which segregation does not occur easily(namely materials that do not have large differences in particle size and density).

Planetary

Planetary mixers involve a mixing drum with an attachment referred to as an agitator or impeller. The agitator rotates in a circular motion to create movement of materials within the vessel. This movement mimics the rotation of planets around the sun, hence, the name planetary. The mixing vessel is stationary in many planetary mixers, but for applications that require additional mixing the bowl can rotate in the opposite direction of the agitator to create more movement of the ingredients. Agitator attachments such as paddles, whisks, or beaters can be affixed to achieve the desired mixing results. An example of this type mixing technology is a stand-up kitchen mixer.

Centrifugal

This technology is often referred to as planetary centrifugal mixing that uses rotation and revolution simultaneously to achieve blendingwithout the use of an agitator. Revolution generates centrifugal forces where the material moves to the exterior of the vessel; rotation and tilting of the vessel causes changes in the direction of the flow, resulting in shearing forces which can quickly generate a high level of heat. The combination of these forces results in quick, uniform mixing and the ability to mix a variety of ingredients including materials with different densities. This mixing method is also able to de-aerate a mixture during mixing, reducing or eliminating time required to de-aerate after the mixing step is completed.

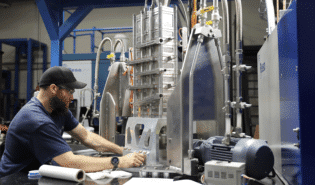

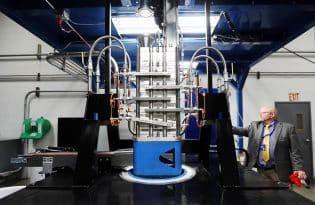

ResonantAcoustic® Mixing (RAM)

RAM technology employs low-frequency energy to generate unique material movement and sound-induced (acoustic) interaction within the vessel without the use of internal, mechanically-driven parts such as an impeller. The combined energy generated by motion and sound imparts a high level of energy to virtually any kind of mix. RAM can impart up to 100 times the force of gravity into mix ingredients, which causes dry or powder particles in the mix to rapidly and continuously collide in a random, chaotic pattern. This results in immediate and continuously efficient mixing. For liquid or viscous mixes, RAM Uniquely generates “fingers” and “cavities” at the interface between liquids and gasses, dramatically increases the surface areas where the materials meet, both speeding and greatly improving mixedness and quality.

RAM results in uniform blending on all levels: macroscopic, microscopic, and even down to molecular-sized particles. RAM can blend virtually any combination of powders, liquids, highly viscous or solids-loaded materials. A single RAM mixer can effectively blend a wide range of ingredients, eliminating the need for multiple specialized mixers their required accessories, and the non-productive task of cleaning those devices while reducing overall capital and operating expenses. Additionally, RAM mixers require little maintenance and can dramatically cut mix times – in many cases from hours to just a few minutes.

To illustrate just how well RAM outperforms traditional mixing methods, here are some results from customer on-site demonstrations:

- In just minutes, RAM effectively mixed ingredients, such as graphene and ceramics, that were previously not possible to mix using traditional mixers

- An aircraft coating company struggled to achieve fine pigment dispersion, but RAM provided 100 percent dispersion is just two minutes

- A biologicscompany could only complete two mix batchesa day with traditional mixers, but achieved 240 batches in a single day using RAM

Resodyn is the only company in the world to offer RAM technology and its unique benefits. It is a ground-up technological departure from traditional industrial mixing methods, and there’s no better way to understand the difference than to witness RAM in action. Request a RAM demonstration today, which can be performed live on-line or on-site at your facility, using your own materials, and solving your uniquely specific mixing challenges. Contact us today to schedule a free demonstration and learn more about how RAM can improve your mixing process and results!

Resodyn Acoustic Mixers – Your Mixing Partner

Resodyn industrial mixing and processing products are made in the USA and are in use in more than 30 countries today. Resodyn’s mixers feature universal processing technology for mixing virtually any kind of material without blades, propellers, baffles, or any other internal engineered mechanical devices. RAM mixers deliver flexible, reliable, and repeatable performance in countless industrial applications from bench-scale development through continuous volume production.

Resodyn’s highly experienced team works with customers to mix virtually every combination of ingredients including liquids, pastes, and powders ranging from nano sizes to large particles as well as highly viscous materials. Resodyn products provide advanced solutions for a broad range of difficult industrial mixing and processing challenges across sectors such as pharmaceuticals, electronics, energetics, adhesives, batteries, advanced and nano-materials and ceramics, as well as many other industries.