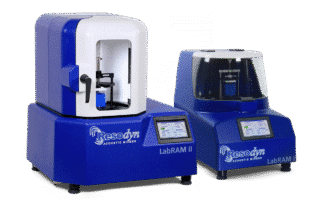

BUTTE, MT - Resodyn Acoustic Mixers announced the newest member of their LabRAM family at the company’s Eighth Annual Technical InterChange Conference in Butte, Montana, called the LabRAM I!

It features up to 100 g of acceleration at 60 Hz for fast, effective, and repeatable processing with a capacity of up to 1.1 lbs. (500 grams), designed for bench-scale development and testing.

In addition to a power increase of up to 10X over the original LabRAM, the LabRAM I features new, robust on-board digital control of machine operations and optional features like vacuum mixing functions and temperature monitoring, all with a maximum noise level of 70 db.

What Is a LabRAM Acoustic Mixer?

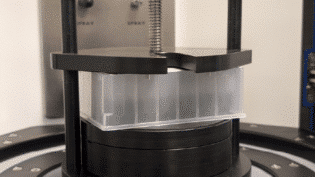

The LabRAM (Laboratory Resonant Acoustic Mixer) is a compact, high-performance mixing device developed by Resodyn Acoustic Mixers. It uses Resonant Acoustic Mixing (RAM)—a bladeless, non-contact mixing technology that applies low-frequency, high-intensity acoustic energy to mix materials.

Instead of using impellers, blades, or paddles, the LabRAM transmits powerful acoustic vibrations directly through the mixing container, causing the contents to mix internally via high-speed agitation.

How It Works (In Simple Terms):

- resonant acoustic waves (typically around 60 Hz).

- These waves transmit through the container into the materials inside.

- The materials undergo intense, uniform agitation—regardless of their viscosity or phase.

- The entire process is completely contactless—nothing touches your product except its container.

Why the LabRAM Is Helpful

1. Mix Virtually Any Material

- Works with powders, liquids, slurries, viscous pastes, gels, suspensions—even reactive or heat-sensitive materials.

2. No Blades = No Cross-Contamination

- Perfect for pharmaceutical, biotech, or chemical applications where cleanliness is critical.

- No cleaning between runs if you use disposable containers.

3. Unmatched Uniformity

- Achieves extremely homogenous mixtures, even for hard-to-blend materials or low-dose APIs.

4. Rapid Mixing Times

- Reduces mix time from hours to minutes (or seconds), especially for high-viscosity or multi-phase materials.

5. Small Footprint, Lab-Ready

- Ideal for R&D, formulation, or QC labs.

- Compatible with various container types (syringes, tubes, jars, etc.).

6. Scalable

- The same technology is used in larger RAM units, making scale-up to pilot and production phases seamless.

Common LabRAM Applications

- Mixing biologics, proteins, or mRNA suspensions (shear-sensitive)

- Uniform coating of particles

- Homogenizing active ingredients in low-dose pharma blends

- Wet and dry milling

- Mechanochemical reactions and material synthesis

- Nanoparticle dispersion and stabilization

View Resodyn's Complete Product Line Industrial Mixers

View Resodyn's Complete Product Line for Pharmaceutical Mixers

View Resodyn's Complete Product Line for Energetics / Hazardous Material Mixers

View Resodyn's Complete Product Line of Processing Accessories