Dry Powder Mixing and Coating with ResonantAcoustic® Technology

Improving Powder Flow, Uniformity, and Processability

Dry powder mixing is a critical and challenging step in pharmaceutical manufacturing. Fine APIs and excipients are often highly cohesive, leading to poor flow, agglomeration, and inconsistent performance in downstream operations such as tablet compression and capsule filling. Overcoming these challenges requires a mixing technology that can efficiently mobilize powders without damaging particles or relying on complex mechanical tooling.

ResonantAcoustic® Mixing (RAM) offers a different approach to dry powder mixing. Instead of using impellers or blades, RAM applies low frequency, high intensity acoustic energy to the entire mixing vessel. This produces homogeneous mixing and distributed shear throughout the powder bed, quickly dispersing materials without localized high stress zones.

Because energy is transferred directly into the powder mass, RAM enables fast, repeatable dry mixing, even for cohesive pharmaceutical powders, without measurable host particle attrition under coated mixing conditions.

Consistent Mixing Without Particle Damage

When evaluated across a range of pharmaceutical powders, including APIs and common excipients with varying particle sizes and chemistries, ResonantAcoustic® Mixing demonstrated effective dry mixing with minimal impact on particle integrity. Particle size distributions remained largely unchanged after processing, indicating that RAM does not induce significant host particle attrition.

In most cases, powders reached a stable, well mixed state within only a few minutes of processing. This rapid mixing highlights the efficiency of resonance driven mixing compared to conventional low shear or mechanically agitated systems.

Dry Powder Coating

Beyond simple blending, ResonantAcoustic® Mixing is highly effective for dry powder coating, a process in which fine guest particles are dispersed onto the surfaces of larger host particles to improve bulk powder behavior.

Dry powder coatings using materials such as silicon dioxide or magnesium stearate are known to reduce interparticle cohesion by increasing surface roughness and spacing between particles. When applied effectively, these coatings lead to higher bulk density, improved flowability, and easier powder handling.

The high, uniform shear generated by RAM promotes intimate contact between guest and host particles, encouraging fine particles to preferentially adhere to host surfaces rather than remaining as loose agglomerates. As a result, RAM can apply dry powder coatings quickly and efficiently, without solvents or binders.

Measurable Improvements in Bulk Density and Flow

Dry powder coating using ResonantAcoustic® Mixing consistently increased bulk density and improved flow performance across multiple pharmaceutical powders. Hydrophobic silicon dioxide was particularly effective, producing the largest gains in bulk density and corresponding increases in flow function coefficient. Magnesium stearate also demonstrated strong performance when sufficient shear was applied.

A clear linear relationship was observed between bulk density and flowability, confirming that improvements in powder packing translated directly into better flow behavior. In most cases, steady state bulk density was achieved in approximately five minutes, making bulk density a practical indicator of coating completeness during development.

A Powerful Tool for Formulation Development

Compared to traditional equipment such as comils, RAM achieved comparable or greater dry coating performance while requiring significantly less material and shorter processing times. This makes ResonantAcoustic® Mixing especially valuable during early formulation development, when API quantities are limited and rapid screening is essential.

By defining the achievable endpoint for bulk density and flow using RAM, formulation teams can establish clear performance targets.

ResonantAcoustic® Mixing: Simplicity with Performance

ResonantAcoustic® Mixing combines fast, uniform dry powder mixing with effective dry powder coating in a single process. The result is improved powder flow, higher bulk density, and greater confidence in downstream processing, delivered through a simple, scalable, and highly controllable technology.

For pharmaceutical powders that challenge conventional mixers, RAM provides a smarter path from development to production.

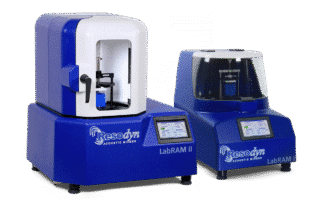

Pharmaceutical Technology published a study by key Pfizer scientists that evaluated the Resodyn LabRAM resonant acoustic mixer as a potential tool for dry powder coating. The study concluded that the LabRAM was effective at applying dry powder coatings with higher bulk density and superior powder flow. Please read this article at:

http://www.pharmtech.com/applying-dry-powder-coatings

The article