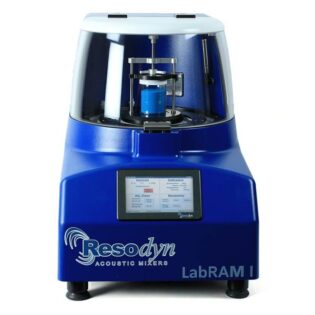

The All-In-One ResonantAcoustic® Processor

When ResonantAcoustic® technology was developed for commercial use (in the 1990’s and early 2000’s), mixing was the target application. Hence, we coined the term ResonantAcoustic® Mixing, or RAM for short. While the technology is still predominantly used for mixing, it is also widely used for other applications as well, namely coating, milling, and sieving.

Many customers have taken advantage of this processing ability to reduce the need for multiple machines, and the various production steps they represent. It's also worth noting that RAM processors are so good at what they do, that pre-processing steps are often no longer required, of course, depending on the material and the details of the application.

The multi-purpose nature of resonant processing often means dramatic cost savings for our customers, from other equipment, processing time, maintenance, and even personnel. This is a big part of what makes RAM one of the most advanced processing technologies in the world.

Let’s take a closer look at each use case:

Mixing

Whether you call it blending, combining, dispersion, or homogenization, mixing is the process of making two separate substances one. The primary quality metric of the mix is uniformity, or how evenly distributed the separate components are after the mixing process. The other key metric is mix time. RAM is exceptional at both achieving high uniformity and incredible speed, often surpassing what is possible by any other means [1].

Coating

Coating larger particles evenly with smaller ones is a useful and very common process. This is done in both dry and wet processes. Available processes vary in size, method, and speed. ResonantAcoustic® coating is extremely efficient just as it is with mixing. Coating powders with RAM is often done dry, without solvents, reducing cost and harmful waste. RAM coating is typically very fast and can often take only seconds for a completely uniform coating [2]. Our customers are using RAM for conductive coatings in battery and electronic production, API coatings in pharmaceutical discovery and production, oxide coating in additive manufacturing, among many other examples.

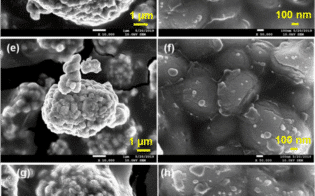

Milling

RAM processors are excellent at breaking down small particles to micron and nano sizes, known as milling or grinding. What makes RAM unique is that it's a low-shear technology. There are no blades to break down materials. Some materials can be milled just through the vertical oscillation of the machine. However, adding milling media to the vessel can also be done to break down a great many materials.

Even when adding milling media, studies have shown [3] that unwanted particle damage is lower with RAM technology than with other mills, resulting in higher yields and more stable particles.

Sieving

By adding vertically stacking sieves into the RAM mixer, material can quickly and easily be sieved. Our customers often use sieve attachments in a laboratory environment, such as for analyzing and tailoring particle size distribution [4].

Multi-Purpose Technology

ResonantAcoustic® technology is ideal for many material processing tasks done both in the lab and on the production floor. Extreme efficiency ensures both rapid and uniform results, and the bladeless, low-shear technology results in less cleanup and waste, zero contamination, greatly reduced particle damage, and improved safety. RAM is both cutting-edge and mature, pushing the boundaries of possibility within the material processing world.

CITATIONS:

- Resodyn Acoustic Mixers for Pharmaceutical and Medical Device Applications, https://www.youtube.com/watch?v=swREVZoqsvQ, Resodyn Acoustic Mixers

- How Chembeads are Made, https://www.youtube.com/watch?v=E1SEd7z-hRQ, AbbVie

- A new and improved method for the preparation of drug nanosuspension formulations using acoustic mixing technology, https://doi.org/10.1016/j.ijpharm.2014.05.003, DH Leung, et al

- Mixing and Manufacturing, https://petersengroup.tamu.edu/facilities/propellant-and-energetics-laboratory/mixing-and-manufacturing/, Texas A&M University Petersen Research Group