Home » Industries Served » Dental Lab Mixing

Dental Labs

#1 Choice for Mixing Equipment

Industrial mixers play a crucial role in the dental process, particularly in the preparation and mixing of materials used in dental procedures. These materials include dental resins, cements, impression materials, and various other compounds that need to be mixed thoroughly for optimal performance. Here's how industrial mixers contribute to the dental process:

1. Preparation of Dental Materials:

Cements and Adhesives: Many dental procedures involve the use of cements, adhesives, and bonding agents that require precise mixing. Industrial mixers ensure these materials are combined uniformly, achieving the correct consistency and chemical properties for proper application.

Impression Materials: Materials like alginate or silicone rubber used for dental impressions need to be mixed to the right viscosity and smoothness. Industrial mixers can automate and standardize this process to ensure accurate and consistent results.

2. Uniform Mixing of Components:

Powder-Liquid Systems: Many dental products, such as dental composites or gypsum products, require the combination of a powder and liquid component. Industrial mixers are designed to ensure that these components are thoroughly blended, preventing clumping or uneven texture that could affect the quality and application of the material.

Consistency and Quality Control: Industrial mixers help maintain a consistent mixing ratio and texture, which is critical for the success of the dental procedure. For example, uneven mixing of cement can result in poor adhesion or premature setting, which may lead to failures in dental restorations.

3. Time Efficiency:

Faster Processing: Industrial mixers can mix dental materials much more quickly than manual methods, helping dental labs and practices save time. This is particularly important in high-demand environments where multiple restorations or impressions may need to be prepared in a short amount of time.

Automation and Precision: Industrial mixers can be programmed to mix materials according to specific parameters, reducing human error and ensuring consistent results every time.

4. Improved Working Conditions:

Safety: Mixing dental materials by hand can expose practitioners to potentially harmful dusts or fumes from materials like gypsum or resins. Industrial mixers can be equipped with enclosed mixing chambers, reducing exposure to hazardous substances.

Reduced Labor Intensity: Automated mixing systems reduce the manual labor involved, which helps alleviate repetitive strain and enhances the overall working conditions for dental technicians.

5. Customization for Specific Applications:

Specialized Mixers for Different Materials: Different dental materials require specific mixing speeds, times, and methods. Industrial mixers in dental labs can be equipped with settings tailored to the specific needs of materials like resin composites, cements, or impression materials, ensuring that the material properties are optimized for use in dental procedures.

In summary, industrial mixers ensure the efficient, uniform, and safe preparation of dental materials, which is vital for the success of various dental treatments and procedures. By improving consistency and reducing labor, they help dental professionals focus on precise application and treatment.

Ours is no ordinary mixer. It's the only one of it's kind. Providing a standardized platform for material processing development, Resodyn Acoustic Mixers, Inc. provides a complete range of mixing equipment geared toward advanced dental laboratory mixing.

This low frequency (60 Hz) mixing system provides unparalleled consistency in performance and repeatability from which to base the advancement of material processing. ResonantAcoustic® Mixing (RAM) technology has been the preferred embodiment for the invention of a multitude of Patent Applications. RAM is simply the “best mode known” for consistent lab scale, bench scale and commercial scale development of mixing innovations.

EXPERT

TESTIMONIALS

“... [ResonantAcoustic® mixing] is a fantastic technology. It has revolutionized the way we mix for development of materials for additive manufacturing...”

- Nik Ninos, Research and Development Manager, Calix Ceramic Solutions

“Resonant acoustic mixers from Resodyn have proven to be extremely valuable in graphene development for our clients. It is critical for nanotechnologies such as graphene to be processed with the level of exacting consistency and particle distribution, especially at low loadings, that RAM has proven to consistently achieve.”

- Research Scientist, European Nanomaterial Research Organization

“[We] mix different rheologies with powder metals, highly viscous, and the LabRAM II has proven it can do that effectively. We’re very impressed with the build quality of the mixer--it’s a nice, solid, well-thought-out piece of equipment. It’s done very well for us.”

- Managing Engineer, Major U.S. Research Laboratory

THE UNIVERSAL DENTAL

LAB MIXING SOLUTION

The ResonantAcoustic® Mixer (RAM) product line harnesses the power of resonance (low-frequency sound) to generate powerful and efficient mixing for dental labs of complex Solid-Solid, Solid-Liquid, Liquid-Gas, and Liquid-Liquid Blends. Benefits include:

- 10-100X faster mixing times

- bladeless non-contact mixing

- consistent homogenization

- no cleaning & no cross contamination

- highly reliable repeatability

- scalable

- built to last decades

- custom engineered systems

- unbeatable mixes

- massive cost savings

- eco-friendly operation

- unmatched safety

HOW RAM MIXERS

CAN HELP YOU

Videos

Industry Folios

Patents

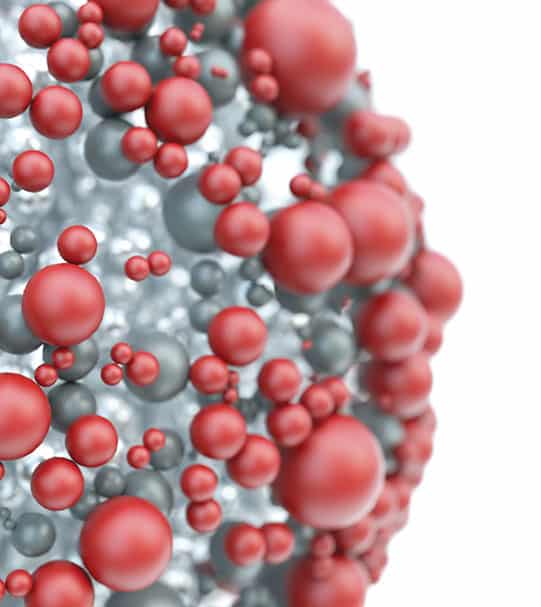

Dissimilar Powder Mixing

Dry ingredients can be difficult to thoroughly and consistently mix, particularly when the particles are of different sizes and characteristics. To illustrate effective and rapid mixing, 10 grams of fumed silica is blended with 100 grams of sand. Completed specimens exhibit no airborne fumed silica, demonstrating uniform blending at an order of magnitude difference in particle size.

Milling and Nano Coating

Coating larger particles with smaller ones is a common processing application, and milling is often a part of the same process. In this video, agglomerated carbon black particles are simultaneously milled to nano size particles that coat the plastic pellets completely in just a few seconds. The high speed video clearly illustrates the dispersion of carbon black particles, their de-agglomeration, and progressive and comprehensive coating of the plastic pellets.

Powder Incorporation in Viscous Liquid

Many polymer-based materials require the addition of dry or powder materials for specific performance characteristics or coloration. To illustrate dry powder incorporation in a viscous liquid, a small amount of dry ingredient is rapidly blended with a viscous liquid. The newly captured mixing phenomena reveal how the thoroughly blended and uniform mixture is achieved in a very short mixing time.

Download these folios of insightful testimonials and links to informative technical papers, articles and patents involving RAM’s impact on the development and use of:

SPECIALTY MATERIALS PROCESSING

PRODUCTS

LabRAM II

1,000 gram capacity for repetitive and small sample processing

Up to 2.2 lb (1,000 gram) payload capacity full-featured, digitally controlled batch mixer for bench-scale development, mixing, and processing.

RAM 55

420 kg capacity delivers bench development through large-scale batch production.

Batch payload capacity up to 924 lbs (420 kg). RAM 55’s digitally controlled, multiple processing capabilities multiply RAM’s value through direct and easy scale-up from bench development to large scale batch production.

Continuous Acoustic Mixer (CAM)

High throughput mixing for pilot and production scale

Continuous Acoustic Mixing (CAM) systems are configurable for OmniRAM, RAM 5, and RAM 55. CAM systems are custom built for the application and enable high-throughput acoustic mixing of powders, pastes, and liquids.