How to Mix Up to 100x Faster With Unbeatable Uniformity, No Cleanup & No Cross Contamination

Difficult-to-mix materials can be processed 10x to 100x faster, more efficiently & consistently. consistently.

Why Choose A ResonantAcoustic® Mixer (RAM)?

The RAM product line harnesses the power of resonance to enable powerful and efficient laboratory mixing of ANY combination of complex materials to include Solid-Solid; Solid-Liquid; Liquid-Gas; Liquid-Liquid and especially Highly Viscous Material Blends.

RAM systems are the Universal Mixing Solution for all mixing requirements and effectively eliminate the need for complex bladed mixing and processing equipment. The more difficult the mix, the better suited our mixer.

Earth's Finest Laboratory Mixer - LabRAM II

- 10x-100x Faster Mixing Times: Accelerates 10x Faster than a fighter jet at up to 100 G's of force.

- Bladeless, Noncontact Mixing: Gentle, yet Amazingly Thorough Mixing driven by random particle motion.

- Exceptional Ingredient Distribution: The Most Consistent Homogenization Available Anywhere.

- Highly Reliable Repeatability: Mix it Exactly How You Want it, Every time, guaranteed.

- Eliminate Time Spent Cleaning: No Blades, Paddles or Impellers to Clean, ever!

- Erase Cross Contamination concerns: Mix in Any Vessel of Your Choosing and Secure it Quickly & easily.

- Hazardous Materials Options Available: Unparalleled Safety for energetics, chemicals & Other Industries.

- Award winning technology: Used in 40+ Countries at Universities, National Labs & Fortune 100 Companies.

- Accessories Include (but not limited to): Vacuum, Jacketed Vessel, and Spray Coating Systems.

ResonantAcoustic® Mixing

Building Blocks

START

Acoustics and Acceleration.

Oscillating at up to 100x the force of gravity (acceleration) RAM technology generates unique material movement and sound-induced interaction delivering speed, quality, convenience and safety.

EXPLORE

Unmatched Processing Versatility.

The common RAM platform across all devices delivers the same performance for powders, liquids, slurries, and high viscosity pastes using the same core technology.

GROW

The Perfect Mix Scales Easily.

RAM technology delivers direct scaling from benchtop mixing and laboratory mixing to production levels with minimal or no adjustments in parameters or timing.

DISCOVER

New-to-the-World Solutions.

RAM delivers new levels of efficiency and quality, leading to new product development, all at higher levels of productivity and profitability.

About Resodyn

Since its introduction to the marketplace in 2007, ResonantAcoustic Mixer’s technology has become the #1 choice for industrial mixing and processing applications. Starting with our world renowned lab mixer, the LabRAM.

RAM’s unique combination of features and performance has proven successful at Fortune 500 laboratories, US National Laboratories and production facilities in 40+ countries across a broad range of industries.

We Serve Every Industry & Application

Mix - Coat - Strip - Grind - Mill - Sieve - Dissolve - Disperse

Adhesives & Sealants

Dental Sector

Chemicals

Cosmetics

Aerospace & Defense

Compounding & Pharma

Battery Energy Storage

3D Printing & Additive Manufacturing

Energetics

Paint, Inks & Coatings

Thermal Management Materials

Polyurethanes

Book a Demo or

Request A Quote Today!

Harness Low-Frequency Sound and Mix the Most Advanced & Effective Products Ever Made.

“In another production-line product we were having spec issues, the test time took on average from 6 to 7 hours. We’ve demonstrated the LabRAM will cut that down to 45 minutes! This is a huge game-changer for us. It has the potential to save us mountains of money because it saves us from producing a lot of bad product by catching it faster than ever before.”

Aaron Sonier

Playlist

The Breakthrough Technology that's Revolutionizing the World of Industrial Mixing.

Our Clients Love Their RAM Mixers

Frequently Asked Questions

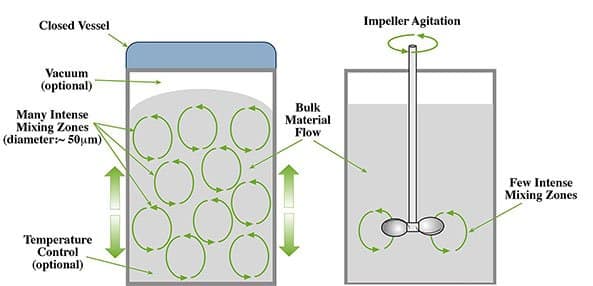

Conventional industrial mixers have many drawbacks. These bladed systems struggle with achieving

consistent results for materials with varying viscosities and/or particle sizes. The mechanical action of the blades

can create excessive shear forces and generate local shear forces that can increase temperatures which can

degrade sensitive materials. High shear forces can alter material properties. RAM’s patented mixing process is

bladeless and effectively rectifies the deficiencies posed by conventional mixing systems. The benefits of RAM

include, but are not limited to dramatically improved mixing times, shear force reduction, minimal overheating

of mixed materials, consistent product homogenization, and repeatable results from mix to mix.

ResonantAcoustic® Mixers deliver a universal platform which produces repeatable results for any

combination of solids, liquids, and gases. RAM is extremely well suited for the challenge of highly viscous

materials. RAM successes include deagglomeration, sieving, and coating.

ResonantAcoustic® Mixing technology has been accepted and utilized worldwide in over 35 countries for a

broad range of industrial applications.

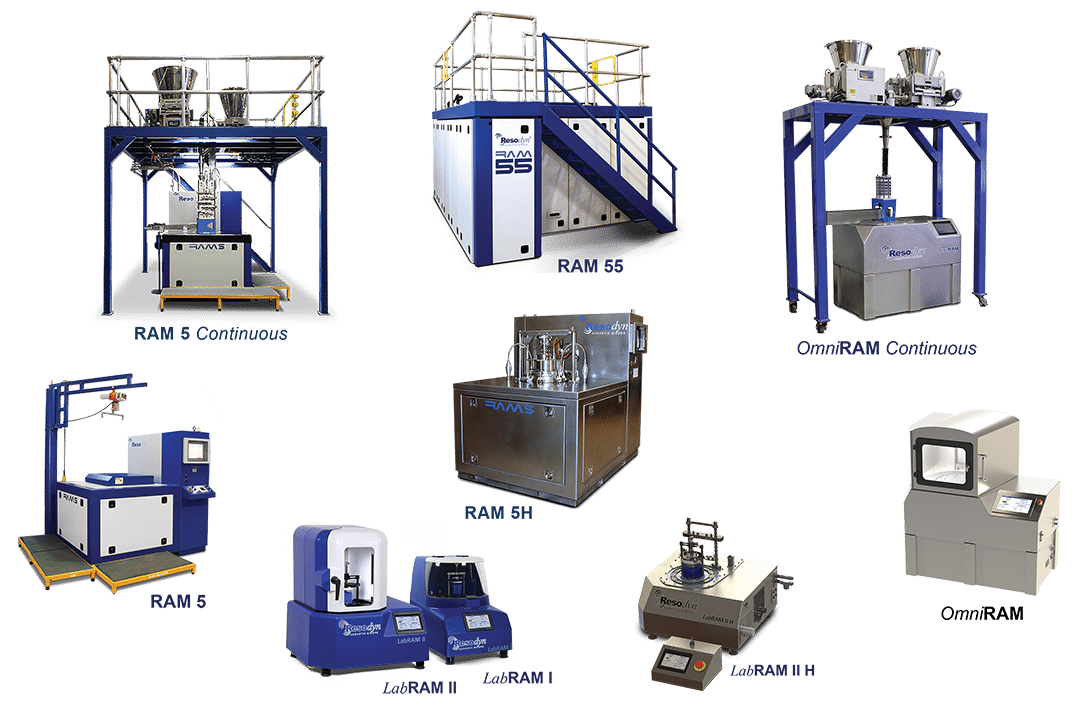

A. ResonantAcoustic® Mixers range in size from bench scale batch production models – LabRAM I (500g

payload capacity) to production scale batch models – RAM 55 (420 kg payload capacity). Resodyn’s Continuous

Acoustic Mixer creates ongoing production capacity of up to thousands of kg/hour.

Resodyn Acoustic Mixers’ external sales team provides both on-site and virtual mixing demonstrations.

Complimentary lab mix testing is also available. For proprietary blends, the company maintains an equipment

rental program (LabRAM I & II) which allows for material process testing in the privacy of your own facility.

Bench scale systems can accommodate any rigid container (glass, metal, or plastic). Production scale systems

are more specific, and the company provides product specific vessels for use with each model.

Yes. With its origination founded in the energetics industry, ResonantAcoustic® Mixers are available

specifically for hazardous material mixing applications. These models are Class I Div. 1 and Class II Div. 1

rated for hazardous material processing. RAM H models are constructed of stainless steel, are redundantly

grounded, and maintain purged enclosures to assure safe operation.

Operator training accompanies every purchase. RAM systems are very user friendly, and the operational

parameters utilized at the bench scale are consistent throughout production scale up. The company offers a

RAM 5 Certification Course and Certificate of Training regarding both operation and maintenance of its

production capacity mixers.

Yes. Due to its inherent safety features, the product’s Safety Record is unblemished and has not resulted in any

reported personal injuries or deaths.

No. RAM systems are acoustically sealed, insulated, and designed to typically be no louder than 70 decibels. Some exceptions may exist with select remote operated units.

RAM batch processing systems are bladeless and self-contained within a closed mixing vessel, preventing

batch cross-contamination and providing ease of cleanup. Resodyn’s Continuous Acoustic Mixer employs a

Clean-In-Place (CIP) process which efficiently cleans the system, reducing waste, and minimizing or possibly

eliminating operator exposure to harmful cleaning agents.

RAM provides for drastically reduced mixing and processing times (10-100 X faster than conventional

mixing equipment) and often results in process step reduction supporting reduced energy consumption. RAM’s

mixing proficiency can result in drastically reduced material waste and can eliminate the need for

solvents/chemicals for various mixing processes. RAM is cleaner than alternative conventional mixing systems.

Made in the USA - Trusted Worldwide