Home » Industries Served by Resonant Acoustic Mixing » Chemicals | Chemical Mixers | Chemical Mixing Equipment | Mechanochemistry

ACCURACY, REPEATABILITY AND PURITY

IN CHEMICAL MIXING & DEVELOPMENT

Chemical mixing and blending applications create unique challenges for conventional industrial mixing systems. Resodyn Acoustic Mixers, Inc. has the experience, knowledge, and product line to solve these challenges and streamline the industrial chemical mixing process.

The chemical blending industry relies on consistency and quality for performance, effectiveness, and value. ResonantAcoustic® Mixers (RAM) deliver safe processing capabilities that expand and expedite product development, and seamlessly scale up to industrial production.

RAM mixers provide 10X to 100X faster mixing and dispersion rates with increased intra-batch uniformity and consistency.

Both heating and cooling systems can be applied for tighter reactive process control and increased consistency of the chemical blending process.

Rapid emulsification and extended life suspensions provide immense benefits to chemical mixing with RAM.

Applications for RAM products in the Chemical Industry is uncapped and inclusive of:

- Catalysts

- Chlorinated Organics

- Epoxy Hardeners

- Floatation Reagents

- Gas Storage Materials

- Lubricant Pastes & Oils

- Mechanochemistry

- Optical Brighteners

- PVB Emulsions

- Specialty Chemicals

- Technical Polymers

- Thermal Transfer Materials

- And Many More

INDUSTRY EXPERT

TESTIMOMIALS

“ResonantAcoustic® Mixing (RAM) enables mechanochemical organic synthesis that avoids milling or crushing media, as well as bulk solvents. The RAM methodology enables significant simplification and improvement of mechanochemical olefin metathesis, the first mechanochemical strategy for ene-yne metathesis, and permits the direct, 200-fold scaling-up of the mechanochemical synthesis of pharmaceutically active sulfonylureas, without any significant changes to reaction conditions or conversion. ”

- Angewandte Chemie International Edition, 2022

“Our Testing with ResonantAcoustic® technology has demonstrated filler incorporation at phenomenal rates and with very little viscous heating. This technology could have a far broader impact on the Chemical Industry than anyone is imagining today”

- Senior Process engineering specialist – Global Chemical Company

“The use of resonant acoustic mixing as a simple, rapid and readily scalable methodology for synthesizing metal–organic frameworks of different levels of complexity, including two- and three-dimensional networks, has been demonstrated”

–Chemical Science, 2020

THE UNIVERSAL BATCH

CHEMICAL MIXING SOLUTION

The ResonantAcoustic® Mixer (RAM) product line harnesses the power of resonance (low-frequency sound) to generate powerful and efficient chemical mixing of complex Solid-Solid, Solid-Liquid, Liquid-Gas, and Liquid-Liquid Blends. RAM systems provide;

- 10-100X faster mixing times

- bladeless non-contact mixing

- consistent homogenization

- end cross contamination

- repeatable

- scalable

- durable

- custom engineered systems

- reliable

- cost savings

- eco-friendly operation

- unmatched safety

Videos on Mechanochemistry and Chemical Mixing

ResonantAcoustic® Mixing (RAM) Mixing Minute - Mechanochemistry

Dr. Tomislav Friščić - Leverhulme International Professor in Green and Sustainable Chemistry at the University of Birmingham in the UK explains the INCREDIBLE benefits of ResonantAcoustic® Mixing (RAM) in the field of Mechanochemistry over legacy technologies at Resodyn's Technical Interchange.

Client Testimonial - Hyaluronic Acid Crosslinking in as little as 1 minute with ResonantAcoustic Mixing!

ResonantAcoustic® Mixing (RAM) for Innovation in Cosmetics and Pharmaceuticals.

Successful application of ResonantAcoustic® Mixing (RAM) technology to Hyaluronic Acid (HA) crosslinking leads to significant technological advantages and at the same time allows crosslinked HA gels.

Polymer and Viscous Liquid Blending in 4 Seconds!

Many polymer based processing applications require additional ingredients for performance or coloration. To illustrate RAM’s ability to quickly and thoroughly mix ingredients of different characteristics, 2.5 grams of food coloring was blended with 235 grams of a polymer surrogate in 4 seconds! The final mixture shows the liquid fully dispersed within the polymer due to the unique and effective mixing action captured in the high speed footage.

Uniform Blending of Dissimilar Powders in 10 Seconds!

Dry ingredients can be difficult to thoroughly and consistently mix, particularly when the particles are of different sizes and characteristics. To illustrate effective and rapid mixing, 10 grams of fumed silica is blended with 100 grams of sand in 10 seconds! Completed specimens exhibit no airborne fumed silica, demonstrating uniform blending at an order of magnitude difference in particle size.

Published Articles on Mechanochemistry and Chemical Mixing

Mechanochemical Synthesis of Boroxine-linked Covalent Organic Frameworks

Materials Chemistry

Real-time Raman spectroscopy permitted the first quantitative kinetic analysis of COF mechanosynthesis, while transferring the reaction design to Resonant Acoustic Mixing (RAM) enabled synthesis of multi-gram amounts of the target COFs.

Hamzehpoor, E., Effaty, F., Borchers, T., Wahrhaftig-Lewis, A., Ottenwaelder, X., Friščić, T., & Perepichka, D. F. (2024). Mechanochemical Synthesis of Boroxine-linked Covalent Organic Frameworks. Materials Chemistry. https://doi.org/10.26434/chemrxiv-2024-d7znt

Enhancement of Co2 Adsorption Kinetics Onto Carbon by Low-Frequency High Amplitude Resonant Vibrations

Carbon Trends

“In this work, a novel strategy is proposed to accelerate the CO2 uptake rate on carbon adsorbents by utilizing Low-Frequency High Amplitude (LFHA) resonant vibratory mixing during the adsorption process to enhance adsorption kinetics.”

Riahi, A., Heggem, E., Caccia, M., & LaDouceur, R. (2024). Enhancement of CO2 Adsorption Kinetics onto Carbon by Low-Frequency High Amplitude Resonant Vibrations. Carbon Trends, 15, 100361. https://doi.org/10.1016/j.cartre.2024.100361

Solvent-free surface modification of milled carbon fiber using resonant acoustic mixing

Applied Surface Science

“Resonant Acoustic Mixing used as a green alternative for surface modification.”

Eyckens, D. J., Hayne, D. J., Henderson, L. C., Howard, S. C., Raeber, T. J., Simons, R., Wilde, A. L., Yalcin, D., & Muir, B. W. (2023). Solvent-free surface modification of milled carbon fiber using resonant acoustic mixing. Applied Surface Science, 646, 158865. https://doi.org/10.1016/j.apsusc.2023.158865

Halogen-bonded cocrystals via resonant acoustic mixing

Mechanochemistry

“We report here on the production of eleven halogen-bonded (XB) cocrystalline architectures via neat and liquid-assisted resonant acoustic mixing (RAM).”

Nari, A., Ovens, J. S., & Bryce, D. L. (2024). Halogen-bonded cocrystals via resonant acoustic mixing. RSC Mechanochemistry, 1(1), 50–62. https://doi.org/10.1039/d3mr00028a

Resonant acoustic mixing (RAM) for efficient mechanoredox catalysis without grinding or impact media

Chemical Communications

RAM proceeds without formal grinding or impact media, is faster than the analogous ball-milling strategy, and is readily scalable.

Effaty, F., Gonnet, L., Koenig, S. G., Nagapudi, K., Ottenwaelder, X., & Friščić, T. (2022). Resonant acoustic mixing (RAM) for efficient mechanoredox catalysis without grinding or impact media. Chemical Communications, 59(8), 1010–1013. https://doi.org/10.1039/d2cc06013b

Milling Media-Free Suzuki Coupling by Direct Mechanocatalysis- From Mixer Mills to Resonant Acoustic Mixers

European Journal

“The RAM exhibits excellent performance in the Suzuki reaction, achieving yields of 90% after 60 minutes and complete conversion after 90 minutes. The longevity of the milling vessel is significantly improved in the RAM. . .”

Wohlgemuth, M., Schmidt, S., Mayer, M., Pickhardt, W., Grätz, S., & Borchardt, L. (2023). Milling Medium‐Free Suzuki coupling by direct mechanocatalysis: from mixer mills to resonant acoustic mixers**. Chemistry - a European Journal, 29(65). https://doi.org/10.1002/chem.202301714

Direct mechanocatalysis by resonant acoustic mixing (RAM)

Chemical Science

“... RAM-based direct mechanocatalysis methodology is simple, enables the effective one-pot, two-step synthesis of triazoles via a combination of benzyl azide formation and CuAAC reactions on a wide scope of reagents, provides control over reaction stoichiometry that is herein shown to be superior ...”

Lennox, C. B., Borchers, T. H., Gonnet, L., Barrett, C. J., Koenig, S. G., Nagapudi, K., & Friščić, T. (2023). Direct mechanocatalysis by resonant acoustic mixing (RAM). Chemical Science, 14(27), 7475–7481. https://doi.org/10.1039/d3sc01591b

The “η-sweet-spot” (ηmax) in liquid-assisted mechanochemistry: polymorph control and the role of a liquid additive as either a catalyst or an inhibitor in resonant acoustic mixing (RAM)

Faraday Discussions

“Resonant acoustic mixing (RAM) offers a simple, efficient route for mechanochemical synthesis in the absence of milling media or bulk solvents. Here, we show the use of RAM to conduct the copper-catalysed coupling of sulfonamides and carbodiimides.”

Gonnet, L., Borchers, T. H., Lennox, C. B., Vainauskas, J., Teoh, Y., Titi, H. M., Barrett, C. J., Koenig, S. G., Nagapudi, K., & Friščić, T. (2023). The “η-sweet-spot” (ηmax) in liquid-assisted mechanochemistry: Polymorph control and the role of a liquid additive as either a catalyst or an inhibitor in resonant acoustic mixing (RAM). Faraday Discussions, 241, 128–149. https://doi.org/10.1039/d2fd00131d

Application of resonant acoustic mixing in the synthesis of vitamin C–nicotinamide variable stoichiometry cocrystals

Faraday Discussions

“The use of resonant acoustic mixing (RAM) to synthesize variable stoichiometry cocrystals of nicotinamide and vitamin C was investigated...LA-RAM is demonstrated to be a scalable, environmentally friendly, ball-free method to make variable stoichiometry cocrystals.”

Bui, M., Chakravarty, P., & Nagapudi, K. (2023). Application of resonant acoustic mixing in the synthesis of vitamin C–nicotinamide variable stoichiometry cocrystals. Faraday Discussions, 241, 357–366. https://doi.org/10.1039/d2fd00124a

Tinkering with Mechanochemical Tools for Scale Up

Angewandte Chemie

“… other mechanochemical syntheses.[37] Liquid-assisted resonant acoustic mixing (LARAM) … rapid adoption at the R&D stage is evidenced by the increasing number of patents filed in the …”

Reynes, J. F., Isoni, V., & García, F. (2023). Tinkering with Mechanochemical Tools for Scale Up. Angewandte Chemie, 135(44). https://doi.org/10.1002/ange.202300819

Metal‐Catalyzed Organic Reactions by Resonant Acoustic Mixing

Angewandte Chemie International Edition

“…catalytic organic synthesis by Resonant Acoustic Mixing (RAM): a mechanochemical methodology that does not require bulk solvent or milling media… Reactions by RAM are readily and directly scaled-up without any significant changes in reaction conditions…”

Gonnet, L., Lennox, C. B., Do, J., Malvestiti, I., Koenig, S. G., Nagapudi, K., & Friščić, T. (2022). Metal‐Catalyzed organic reactions by resonant acoustic mixing**. Angewandte Chemie International Edition, 61(13). https://doi.org/10.1002/anie.202115030

Resonant acoustic-mixing technology as a novel method for production of negative-temperature coefficient thermistors

Journal of Materials Science Materials in Electronics

“...This study will be the lead to guide future studies into the cost-effective fast fabrication of negative-temperature coefficient thermistors by resonant acoustic mixing technology due to reduction of manufacturing costs by reducing processing time.”

Price, B. Y., & Kennedy, S. R. (2022b). Resonant acoustic-mixing technology as a novel method for production of negative-temperature coefficient thermistors. Journal of Materials Science Materials in Electronics, 33(14), 11380–11391. https://doi.org/10.1007/s10854-022-08110-2

Time‐resolved in situ monitoring of mechanochemical reactions

Angewandte Chemie International Edition

“… resonant acoustic mixing (RAM) cocrystallization of carbamazepine and nicotinamide by TRIS-XRD, the degree of bulk powder ...”

Michalchuk, A. A., & Emmerling, F. (2022). Time‐resolved in situ monitoring of mechanochemical reactions. Angewandte Chemie International Edition, 61(21). https://doi.org/10.1002/anie.202117270

Application of mechanochemical activation in synthetic organic chemistry

Nontraditional Activation Methods in Green and Sustainable Applications

" … A recently emerged technique is Resonant Acoustic Mixing (RAM), which uses low-…”

Varga, G., Sipos, P., & Pálinkó, I. (2021). Application of mechanochemical activation in Synthetic Organic Chemistry. Nontraditional Activation Methods in Green and Sustainable Applications, 453–466. https://doi.org/10.1016/b978-0-12-819009-8.00001-3

Simple, scalable mechanosynthesis of metal–organic frameworks using liquid-assisted resonant acoustic mixing (LA-RAM)

Chemical Science

“… mechanochemical syntheses. We demonstrate the use of liquid-assisted resonant acoustic mixing … never been previously obtained in a mechanochemical environment ...”

Titi, H. M., Do, J., Howarth, A. J., Nagapudi, K., & Friščić, T. (2020). Simple, scalable mechanosynthesis of metal–organic frameworks using liquid-assisted resonant acoustic mixing (LA-RAM). Chemical Science, 11(29), 7578–7584. https://doi.org/10.1039/d0sc00333f

Mechanochemistry for organic chemists: An update

European Journal of Organic Chemistry

“… A recently emerged technique is Resonant Acoustic Mixing (RAM), which uses low-frequency, high-amplitude acoustic resonance to agitate powder samples.”

Tan, D., & Friščić, T. (2017). Mechanochemistry for Organic Chemists: An update. European Journal of Organic Chemistry, 2018(1), 18–33. https://doi.org/10.1002/ejoc.201700961

Ball-free mechanochemistry: in situ real-time monitoring of pharmaceutical co-crystal formation by resonant acoustic mixing

Chemical Communications

“We present here the first in situ study of RAM-induced co-crystallisation monitored using synchrotron X-ray powder diffraction.”

Michalchuk, A. a. L., Hope, K. S., Kennedy, S. R., Blanco, M. V., Boldyreva, E. V., & Pulham, C. R. (2018). Ball-free mechanochemistry: in situ real-time monitoring of pharmaceutical co-crystal formation by resonant acoustic mixing. Chemical Communications, 54(32), 4033–4036. https://doi.org/10.1039/c8cc02187b

High-throughput screening and scaleup of cocrystals using resonant acoustic mixing

International Journal of Pharmaceutics

“This paper explores the effectiveness of resonant acoustic mixing RAM for screening and scale up of cocrystals. . . . Theophylline Oxalic acid cocrystals at an 80 gram scale with a net yield of 94%. RAM is thus established as an environmentally friendly mechanochemical technique for both high throughput screening and scaled up production of cocrystals.

Nagapudi, K., Umanzor, E. Y., & Masui, C. (2017). High-throughput screening and scale-up of cocrystals using resonant acoustic mixing. International Journal of Pharmaceutics, 521(1–2), 337–345. https://doi.org/10.1016/j.ijpharm.2017.02.027

Relevant Patents for Mechanochemistry and Chemical Mixing

Approved and pending applications for work involving the use of ResonantAcoustic® mixing technology.

US US20240024241A1 Rajesh N. Dave, Sangah Kim & Zhixing Lin New Jersey Institute Of Technology

Priority 2022-07-12 • Filed 2023-07-12 • Published 2024-01-25

High(greater than 30%) and/or low(less than 10%) loaded multiple API powdered/nanoparticle were tabulated with increased flowability and physical properties. Properties include blend flowability and uniformity, bulk packing density, compactability, tensile strength, and dissolution. Blending is done through solventless dry mechanical coating of at least one minority API component defined as the API component with the least weight per volume surface coated with nano-sized powders in lesser amounts by wt % of the blend, and preferably less than 10% dry coated of the minority API. An excipient may be dry coated in the lesser amount wherein the excipient is a minority component. Both minority excipient and minority API may be dry coated. Using dry coating instead of dry granulation and/or wet granulation techniques in producing tablets saves manufacturing steps, costs, and produces higher quality tablets with surprisingly higher properties than expected for low flowability solid powdered ingredients.

Highlighted Use: A LabRAM coated an API with Aerosil A200.

Composition, magnetic particle-containing film, and electronic component

WO EP US JP TW US20230238164A1 Tatsuo Ishikawa Fujifilm Corporation

Priority 2020-09-18 • Filed 2023-03-15 • Published 2023-07-27

An object of the present invention is to provide a composition that can form a magnetic particle-containing film having excellent magnetic permeability and excellent acid resistance, and has excellent sedimentation stability. Another object of the present invention is to provide a magnetic particle-containing film that relates to the composition, and an electronic component that includes the magnetic particle-containing film. The composition according to an embodiment of the present invention contains magnetic particles that contain 70% to 90% by mass of Fe atoms and have a crystal structure of Fe, an average particle diameter of 2 to 30 μm, and an aspect ratio less than 8, and a rheology control agent.

Highlighted Use: RAM technology created a stable material with excellent magnetic anisotropy.

Method for production of composite magnetic powders by autonomous grinding

SK SK132021A3, Bureš Radovan, Fáberová Mária

Priority 2021-2-25 • Filed 2021-2-25 • Published 2022-9-14

Ferromagnetism in the form of powdered magnetically soft metal or alloy is placed together with electro-insulating ceramic powder in a cylindrical container. The ratio of the height to the diameter of the container is 2:1. The container is filled with powder to a maximum of 1/3 of the volume. The powder mixture is autonomously ground by the action of resonant acoustic energy for 15 minutes to 360 hours. The particles of the powder mixture are given a gravitational acceleration of at least 20 g. Ferromagnetic particles are at least one order of magnitude larger than ceramic particles. Particles of the powder mixture are precipitated, ceramic particles are fragmented into smaller particles. Ferromagnetic particles act as a grinding medium. Fragmented ceramic particles are attached to the surface of ferromagnetic particles, the size of which does not change significantly during autonomous grinding. The powder composite material is further processed by pressing and sintering into magnetically soft components.

Highlighted Use: RAM combined ferromagnetic and ceramic particles.

Complexes Comprising Carbohydrate Polymers and Active Ingredients and Methods for Their Preparation

WO, EP, AU, JP, CA, US, JP2023510089A Felix Polyak, Dmitry Budovich

Priority 2019-12-13 • Filed 2020-12-11 • Published 2023-3-13

Disclosed herein are molecular complexes and compositions containing them. More specifically, carbohydrate polymers such as hyaluronic acid and its salts are bioactive selected from natural products and nutrients (amino acids, amino esters, hydroxy acids, hydroxy esters, vitamins, cannabinoids, etc.) and active pharmaceutical

ingredients. Complexes with compounds to form stable molecular complexes. Complexation can be conveniently achieved using resonant acoustic mixing methods.

Highlighted Use: RAM technology combined carbohydrate polymers and biologically active compounds.

A method to produce and scale-up cocrystals and salts via resonant acoustic mixing

US, EP EP2845852A1 Jerry Salan, Stephen R. Anderson, and David J. Am Ende, Nalas Engineering Services Inc.

Priority 2013-9-4 • Filed 2014-9-4 • Published 2015-3-11

A method to produce and manufacture cocrystals and salts is disclosed wherein crystalline solids and other components were combined in the desired proportions into a mixing chamber and mixed at high intensity to afford a cocrystalline product. No grinding media were required. The mixing system consists of a resonant acoustic vibratory system capable of supplying a large amount of energy to the mixture and is tunable to a desired resonance frequency and amplitude. The use of resonant acoustic mixing to assist cocrystallization is novel. This discovery enables the manufacture of cocrystals and salt forms, simplifying their manufacture and scale-up, and avoiding the use of grinding methods or grinding media. The present invention affords the manufacture of cocrystals and salts on kilogram to multi-ton scale and is adaptable to continuous manufacturing through the use of resonant mixing methods.

Highlighted Use: RAM technology can eliminate solvents and grinding material.

White Papers for Chemical Mixing

Folio for Mechanochemistry

CHEMICAL MIXING

PROCESSING PRODUCTS

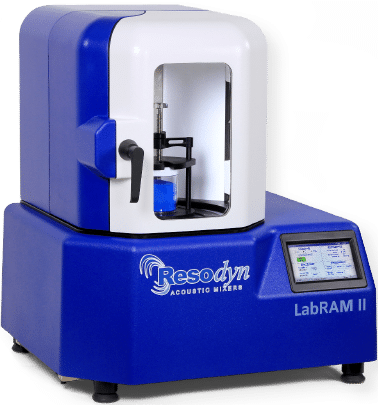

LabRAM II

1,000 gram capacity for development

Up to 2.2 lb (1,000 gram) payload capacity full-featured, digitally controlled batch mixer for bench-scale development, mixing, and processing.

OmniRAM

5 kg capacity for pilot-scale production

Up to 2.2 lb (1,000 gram) payload capacity full-featured, digitally controlled batch mixer for bench-scale development, mixing, and processing.

RAM 5

36 kg capacity for pilot and production scale

80 lb (36 kg) payload capacity, digitally controlled, batch mixer with multiple processing capabilities and options for pilot production and processing.

Get a FREE ResonantAcoustic Mixing Demo Today!

We can schedule an on-site or online video demonstration with a LabRAM I or II (bench scale) mixer to show you the incredible versatility of RAM technology. We can mix any materials you wish to test, and we love challenging mixes!