RAM is changing processing paradigms in these industries, delivering critical results with speed and efficiency never before possible.

RAM technology is rapidly gaining adoption across a wide range of industries and applications. Whether you are already using RAM technology in a new and exciting way or you have questions about a potential new application, please get in touch.

Resodyn Acoustic Mixers enable products and processes never before possible. Click here for a list of Resodyn’s own patents along with dozens more filed by our customers that embody RAM technology.

Edit

500 Capacity (grams) Acceleration (g) 100 70 db Max Butte, MT – Resodyn Acoustic Mixers…

Read More

Edit

Larry Farrar Opens TI-18 The TI-18 Classroom Jennifer Breitbach leads a session. RAM 5 Batch…

Read More

Edit

Innovative Mixing Manufacturer Introduces 2nd Generation Acoustic Mixer for Hazardous Environments BUTTE, MT – Resodyn Acoustic…

Read More

Energy storage technologies rely on special materials and methods, and demand breakthrough processing capabilities. ResonantAcoustic® Mixing (RAM) technology surpasses every traditional method with material and precursor processing capabilities that support and drive new energy storage solutions.

Virtually Any Material

RAM’s intense yet gentle processing technology processes materials of nearly any particle size or behavior. Whether cohesive, agglomerated, nano-scale, or temperature sensitive, RAM’s features can control temperatures, apply vacuum, dry or spray coat one particle on another, and effectively process any combination of powders, liquids, highly viscous or solids-loaded materials.

Single Technology Platform

The world’s top pharmaceutical firms already rely on RAM’s ability to instantly switch from one set of ingredient characteristics to another, while changing only the processing vessel and the mixing parameters. Cross-contamination, excess movement, and material handling are minimized.

Sound Energy Does the Work

RAM technology uses low-frequency sound energy to thoroughly mix particles of often vastly different characteristics. Mix times of hours are frequently reduced to minutes and previously unmixable ingredients are dispersed uniformly and thoroughly.

1,000 gram capacity for energetics development

304L stainless steel housing and designed for remote operation. Rated for Class I Division I and Class II Division I material processing.

5 kg capacity for pilot-scale production

Onboard operating system with recipe development and memory, real-time parameter monitoring, 100% processing data retention, multiple operator security levels. RAM technology scales easily without additional testing from pilot to production scales.

36 kg capacity for pilot and production scale

Allows fast and efficient scale up from bench scale equipment with a full capabilities menu of temperature monitoring and control, mixing under vacuum, recipe development and retention, real-time parameter monitoring and recording, 100% processing data retention, multiple operator security levels, and product extraction options.

Videos

Case Studies

White Papers

Patents

Articles

Dissimilar Powder Mixing

Dry ingredients can be difficult to thoroughly and consistently mix, particularly when the particles are of different sizes and characteristics. To illustrate effective and rapid mixing, 10 grams of fumed silica is blended with 100 grams of sand. Completed specimens exhibit no airborne fumed silica, demonstrating uniform blending at an order of magnitude difference in particle size.

Milling and Nano Coating

Coating larger particles with smaller ones is a common processing application, and milling is often a part of the same process. In this video, agglomerated carbon black particles are simultaneously milled to nano size particles that coat the plastic pellets completely in just a few seconds. The high speed video clearly illustrates the dispersion of carbon black particles, their de-agglomeration, and progressive and comprehensive coating of the plastic pellets.

White Paper 1 – Brief description of this paper.

Poster 1 – Brief description of this poster.

White Paper 2 – Brief description of this paper.

White Paper 2 – Brief description of this paper.

Poster 2 – Brief description of this case poster.

White Paper 3 – Brief description of this paper.

Etc.

Link to relevant content on our patent list page.

Links to selected related articles – off-site links

Ceramic materials have made their way into previously unimagined arenas in electronics, energy, defense, construction, and medicine. Each of these applications rely on the demanding and exacting processing performance of ResonantAcoustic® Mixing (RAM) technology.

Virtually Any Material

RAM’s intense yet gentle processing technology processes materials of nearly any particle size or behavior. Whether cohesive, agglomerated, nano-scale, or temperature sensitive, RAM’s features can control temperatures, apply vacuum, dry or spray coat one particle on another, and effectively process any combination of powders, liquids, highly viscous or solids-loaded materials.

Single Technology Platform

The world’s top pharmaceutical firms already rely on RAM’s ability to instantly switch from one set of ingredient characteristics to another, while changing only the processing vessel and the mixing parameters. Cross-contamination, excess movement, and material handling are minimized.

Sound Energy Does the Work

RAM technology uses low-frequency sound energy to thoroughly mix particles of often vastly different characteristics. Mix times of hours are frequently reduced to minutes and previously unmixable ingredients are dispersed uniformly and thoroughly.

1,000 gram capacity for energetics development

304L stainless steel housing and designed for remote operation. Rated for Class I Division I and Class II Division I material processing.

5 kg capacity for pilot-scale production

Onboard operating system with recipe development and memory, real-time parameter monitoring, 100% processing data retention, multiple operator security levels. RAM technology scales easily without additional testing from pilot to production scales.

36 kg capacity for pilot and production scale

Allows fast and efficient scale up from bench scale equipment with a full capabilities menu of temperature monitoring and control, mixing under vacuum, recipe development and retention, real-time parameter monitoring and recording, 100% processing data retention, multiple operator security levels, and product extraction options.

Videos

Case Studies

White Papers

Patents

Articles

Dissimilar Powder Mixing

Dry ingredients can be difficult to thoroughly and consistently mix, particularly when the particles are of different sizes and characteristics. To illustrate effective and rapid mixing, 10 grams of fumed silica is blended with 100 grams of sand. Completed specimens exhibit no airborne fumed silica, demonstrating uniform blending at an order of magnitude difference in particle size.

Milling and Nano Coating

Coating larger particles with smaller ones is a common processing application, and milling is often a part of the same process. In this video, agglomerated carbon black particles are simultaneously milled to nano size particles that coat the plastic pellets completely in just a few seconds. The high speed video clearly illustrates the dispersion of carbon black particles, their de-agglomeration, and progressive and comprehensive coating of the plastic pellets.

White Paper 1 – Brief description of this paper.

Poster 1 – Brief description of this poster.

White Paper 2 – Brief description of this paper.

White Paper 2 – Brief description of this paper.

Poster 2 – Brief description of this case poster.

White Paper 3 – Brief description of this paper.

Etc.

Link to relevant content on our patent list page.

Links to selected related articles – off-site links

The chemical industry relies on consistency and quality for performance, effectiveness and brand value. ResonantAcoustic® Mixing (RAM) delivers mixing and processing capabilities that expand and speed product development, quality processes, and pilot scale production.

• 10 x faster mixing and dispersion

• Very low in-batch variation

• Intra-batch uniformity and consistency

• Rapid emulsification

• Extended life suspensions

Virtually Any Material

RAM’s intense yet gentle processing technology processes materials of nearly any particle size or behavior. Whether cohesive, agglomerated, nano-scale, or temperature sensitive, RAM’s features can control temperatures, apply vacuum, dry or spray coat one particle on another, and effectively process any combination of powders, liquids, highly viscous or solids-loaded materials.

Single Technology Platform

The world’s top pharmaceutical firms already rely on RAM’s ability to instantly switch from one set of ingredient characteristics to another, while changing only the processing vessel and the mixing parameters. Cross-contamination, excess movement, and material handling are minimized.

Sound Energy Does the Work

RAM technology uses low-frequency sound energy to thoroughly mix particles of often vastly different characteristics. Mix times of hours are frequently reduced to minutes and previously unmixable ingredients are dispersed uniformly and thoroughly.

1,000 gram capacity for development

304L stainless steel housing and designed for remote operation. Rated for Class I Division I and Class II Division I material processing.

5 kg capacity for pilot-scale production

Onboard operating system with recipe development and memory, real-time parameter monitoring, 100% processing data retention, multiple operator security levels. RAM technology scales easily without additional testing from pilot to production scales.

36 kg capacity for pilot and production scale

Allows fast and efficient scale up from bench scale equipment with a full capabilities menu of temperature monitoring and control, mixing under vacuum, recipe development and retention, real-time parameter monitoring and recording, 100% processing data retention, multiple operator security levels, and product extraction options.

Videos

Case Studies

White Papers

Patents

Articles

Dissimilar Powder Mixing

Dry ingredients can be difficult to thoroughly and consistently mix, particularly when the particles are of different sizes and characteristics. To illustrate effective and rapid mixing, 10 grams of fumed silica is blended with 100 grams of sand. Completed specimens exhibit no airborne fumed silica, demonstrating uniform blending at an order of magnitude difference in particle size.

Milling and Nano Coating

Coating larger particles with smaller ones is a common processing application, and milling is often a part of the same process. In this video, agglomerated carbon black particles are simultaneously milled to nano size particles that coat the plastic pellets completely in just a few seconds. The high speed video clearly illustrates the dispersion of carbon black particles, their de-agglomeration, and progressive and comprehensive coating of the plastic pellets.

White Paper 1 – Brief description of this paper.

Poster 1 – Brief description of this poster.

White Paper 2 – Brief description of this paper.

White Paper 2 – Brief description of this paper.

Poster 2 – Brief description of this case poster.

White Paper 3 – Brief description of this paper.

Etc.

Link to relevant content on our patent list page.

Links to selected related articles – off-site links

In the industry where RAM technology was born, ResonantAcoustic® Mixing (RAM) technology continues to expand deeper into areas of material development, processing quality, larger scale production capabilities, and continuous production systems.

Virtually Any Material

RAM’s intense yet gentle processing technology processes materials of nearly any particle size or behavior. Whether cohesive, agglomerated, nano-scale, or temperature sensitive, RAM’s features can control temperatures, apply vacuum, dry or spray coat one particle on another, and effectively process any combination of powders, liquids, highly viscous or solids-loaded materials.

Single Technology Platform

The world’s top pharmaceutical firms already rely on RAM’s ability to instantly switch from one set of ingredient characteristics to another, while changing only the processing vessel and the mixing parameters. Cross-contamination, excess movement, and material handling are minimized.

Sound Energy Does the Work

RAM technology uses low-frequency sound energy to thoroughly mix particles of often vastly different characteristics. Mix times of hours are frequently reduced to minutes and previously unmixable ingredients are dispersed uniformly and thoroughly.

1,000 gram capacity for energetics development

304L stainless steel housing and designed for remote operation. Rated for Class I Division I and Class II Division I material processing.

5 kg capacity for pilot-scale production

Onboard operating system with recipe development and memory, real-time parameter monitoring, 100% processing data retention, multiple operator security levels. RAM technology scales easily without additional testing from pilot to production scales.

36 kg capacity for pilot and production scale

Allows fast and efficient scale up from bench scale equipment with a full capabilities menu of temperature monitoring and control, mixing under vacuum, recipe development and retention, real-time parameter monitoring and recording, 100% processing data retention, multiple operator security levels, and product extraction options.

Videos

Case Studies

White Papers

Patents

Articles

Dissimilar Powder Mixing

Dry ingredients can be difficult to thoroughly and consistently mix, particularly when the particles are of different sizes and characteristics. To illustrate effective and rapid mixing, 10 grams of fumed silica is blended with 100 grams of sand. Completed specimens exhibit no airborne fumed silica, demonstrating uniform blending at an order of magnitude difference in particle size.

Milling and Nano Coating

Coating larger particles with smaller ones is a common processing application, and milling is often a part of the same process. In this video, agglomerated carbon black particles are simultaneously milled to nano size particles that coat the plastic pellets completely in just a few seconds. The high speed video clearly illustrates the dispersion of carbon black particles, their de-agglomeration, and progressive and comprehensive coating of the plastic pellets.

White Paper 1 – Brief description of this paper.

Poster 1 – Brief description of this poster.

White Paper 2 – Brief description of this paper.

White Paper 2 – Brief description of this paper.

Poster 2 – Brief description of this case poster.

White Paper 3 – Brief description of this paper.

Etc.

Link to relevant content on our patent list page.

Links to selected related articles – off-site links

Pharmaceutical developers and manufacturers around the world are discovering and exploiting key performance characteristics of RAM processing that deliver

Virtually Any Material

RAM’s intense yet gentle processing technology processes materials of nearly any particle size or behavior. Whether cohesive, agglomerated, nano-scale, or temperature sensitive, RAM’s features can control temperatures, apply vacuum, dry or spray coat one particle on another, and effectively process any combination of powders, liquids, highly viscous or solids-loaded materials.

Single Technology Platform

The world’s top pharmaceutical firms already rely on RAM’s ability to instantly switch from one set of ingredient characteristics to another, while changing only the processing vessel and the mixing parameters. Cross-contamination, excess movement, and material handling are minimized.

Sound Energy Does the Work

RAM technology uses low-frequency sound energy to thoroughly mix particles of often vastly different characteristics. Mix times of hours are frequently reduced to minutes and previously unmixable ingredients are dispersed uniformly and thoroughly.

500 gram capacity for repetitive and small sample processing

Simple, rapid controls allow processing of small samples on the same technology platform as LabRAM II for repetitive and precursor processes, and vacuum capability.

1 kg capacity delivers bench-scale development capabilities

Onboard operating system with recipe development and memory, real-time parameter monitoring, 100% processing data retention, multiple operator security levels. RAM technology scales easily without additional testing from development to pilot to production scales.

36 kg capacity for pilot and production scale

Allows fast and efficient scale up from bench scale equipment with a full capabilities menu of temperature monitoring and control, mixing under vacuum, recipe development and retention, real-time parameter monitoring and recording, 100% processing data retention, multiple operator security levels, and product extraction options.

Videos

Case Studies

White Papers

Patents

Articles

Dissimilar Powder Mixing

Dry ingredients can be difficult to thoroughly and consistently mix, particularly when the particles are of different sizes and characteristics. To illustrate effective and rapid mixing, 10 grams of fumed silica is blended with 100 grams of sand. Completed specimens exhibit no airborne fumed silica, demonstrating uniform blending at an order of magnitude difference in particle size.

Milling and Nano Coating

Coating larger particles with smaller ones is a common processing application, and milling is often a part of the same process. In this video, agglomerated carbon black particles are simultaneously milled to nano size particles that coat the plastic pellets completely in just a few seconds. The high speed video clearly illustrates the dispersion of carbon black particles, their de-agglomeration, and progressive and comprehensive coating of the plastic pellets.

White Paper 1 – Brief description of this paper.

Poster 1 – Brief description of this poster.

White Paper 2 – Brief description of this paper.

White Paper 2 – Brief description of this paper.

Poster 2 – Brief description of this case poster.

White Paper 3 – Brief description of this paper.

Etc.

Link to relevant content on our patent list page.

Links to selected related articles – off-site links

[awsmjobs]

Edit

500 Capacity (grams) Acceleration (g) 100 70 db Max Butte, MT – Resodyn Acoustic Mixers…

Read More

Edit

Larry Farrar Opens TI-18 The TI-18 Classroom Jennifer Breitbach leads a session. RAM 5 Batch…

Read More

vamtam-theme-circle-post

vamtam-theme-circle-post

Edit

Resodyn representatives Lawrence C. Farrar, President and C.E.O., and Mike Miller, Senior Chemical Engineer, joined…

Read More

Edit

Resodyn Acoustic Mixers Continues to Change How You Think About Mixing and Processing August 23,…

Read More

vamtam-theme-circle-post

vamtam-theme-circle-post

Edit

SERDP/ESTCP has been utilizing RAM Technology for several projects. This particular project will demonstrate the…

Read More

vamtam-theme-circle-post

vamtam-theme-circle-post

Edit

Innovative Mixing Manufacturer Introduces 2nd Generation Acoustic Mixer for Wide Array of Applications BUTTE, MT –…

Read More

vamtam-theme-circle-post

vamtam-theme-circle-post

Edit

Innovative Mixing Manufacturer Introduces 2nd Generation Acoustic Mixer for Hazardous Environments BUTTE, MT – Resodyn Acoustic…

Read More

vamtam-theme-circle-post

vamtam-theme-circle-post

Edit

We are excited to be joining over 5,000 attendees from across the country this spring…

Read More

Edit

Butte, MT – Resodyn Acoustic Mixers announced the completion of its initial launch distribution of…

Read More

Page 1 of 21

2

Next

Notice: JavaScript is required for this content.

Generally, you can visit this website without revealing any personal information about yourself. At times though, we may need information about you. Unless otherwise indicated, the information we request is optional. We will specify which information is mandatory at the appropriate data entry points.

If you chose to provide us with personal information that we, or the companies doing business with us, may need, we will use such information in accordance with this policy. If you ask us to not use this information as a basis for further contact with you, we will respect your request.

Our website collects information from our Contact Forms. These forms request that you give us contact information (name, email address, and other items). It is never necessary to provide your personal information or credit card information on our website.

We may use contact information to (i) send you information about our company and promotional material from the businesses doing business with us; (ii) contact you when necessary. As stated below, you may opt-out of being contacted in the future.

We may perform statistical analyses of behaviors and characteristics in order to measure interest in and use of the various areas of the site.

Our website recognizes information about your computer, such as the browser, operating system, IP address, and the home server from which you access the Internet. We keep track of the domains from which people visit our website. Your IP address is used to help identify you, gather broad demographic data, identify trends and statistics, help diagnose problems with our server, and to administer our website. We may use your IP address information when compiling and reporting aggregate information to companies doing business with us. We normally do not link IP addresses to any personally identifiable information; however, when we feel it is necessary to enforce compliance with our terms of service or to protect our service, website, customers, visitors, or others, we may use IP addresses to identify a visitor.

Our site uses “cookies” to provide information on your computer. Cookies are pieces of data that a website can send to your browser, which may then be stored on your hard drive.

www.resodynmixers.com may contain links to other websites. We are not responsible for the privacy practices or the content of these other sites. You should check the privacy policies of these other websites when providing personally identifiable information.

You may, at any time, review, edit, and/or remove any information we have stored on you by contacting Resodyn Acoustic Mixers through e-mail at info@resodynmixers.com. We will promptly comply with any request to review, edit, or remove information.

Resodyn Acoustic Mixers cannot and does not ensure or warrant the security of any information you transmit to us or from our website. You transmit information to us at your own risk. Once we receive your transmission, we make our best effort to ensure its security on our systems.

If you have any questions about this privacy policy or the practices of this website, please contact:

Resodyn Acoustic Mixers

130 N. Main Street

Suite 600

Butte, Montana 59701

USA

Phone: 406.497.5333

Email: info@resodynmixers.com

Acoustics and Acceleration

Oscillating at up to 100x the force of gravity (acceleration) RAM technology generates unique material movement and sound-induced interaction delivering speed, quality, convenience, and safety.

Unmatched Processing Versatility

The common RAM platform across all devices delivers the same performance for powders, liquids, slurries, and high viscosity pastes using the same core technology.

The Perfect Mix Scales Easily

RAM technology delivers direct scaling from bench to production levels with minimal or no adjustments in parameters or timing.

New-to-the-World Solutions

RAM delivers new levels of efficiency and quality, leading to new product development, all at higher levels of productivity and profitability.

ResonantAcoustic® Mixing Technology is unique to Resodyn Acoustic Mixers and is protected by numerous US Patents. Core patents are listed below.

ResonantAcoustic® Mixing Technology enables the development of novel products and processes and is embodied in dozens of United States and International patents. The list below is not intended to be comprehensive, but please contact us if you find errors or know if a patent that should be added to the list.

RAM uses low frequency sound energy to deliver proven benefits in mixing speed, quality, and versatility. Resodyn’s own researchers and Resodyn customers around the world are discovering new techniques, new processes, and new applications every day, expanding RAM’s already industry-leading versatility.

The Resodyn Technical Library serves as a central knowledge base for documentation, white papers, technical bulletins, videos, and data sheets.

The Mixer Trial Rental Program allows customers to develop and optimize mixing tests on-site before committing to a purchase. Bench scale

A core element of ResonantAcoustic® Mixing’s effectiveness is a relentless attention to material, process, and repeatability. Experienced Resodyn engineers and technicians develop test plans, perform them, and document each step. Every final report focuses on your materials, successful RAM processing, and recommended mixing solutions.

Learn More

ResonantAcoustic® technology enables the mixing and processing of materials that challenge traditional mixers, often leading to new methods, processes, and solutions. A broad array of material, process, and production solutions are available through Resodyn’s individually tailored process development services.

Learn More

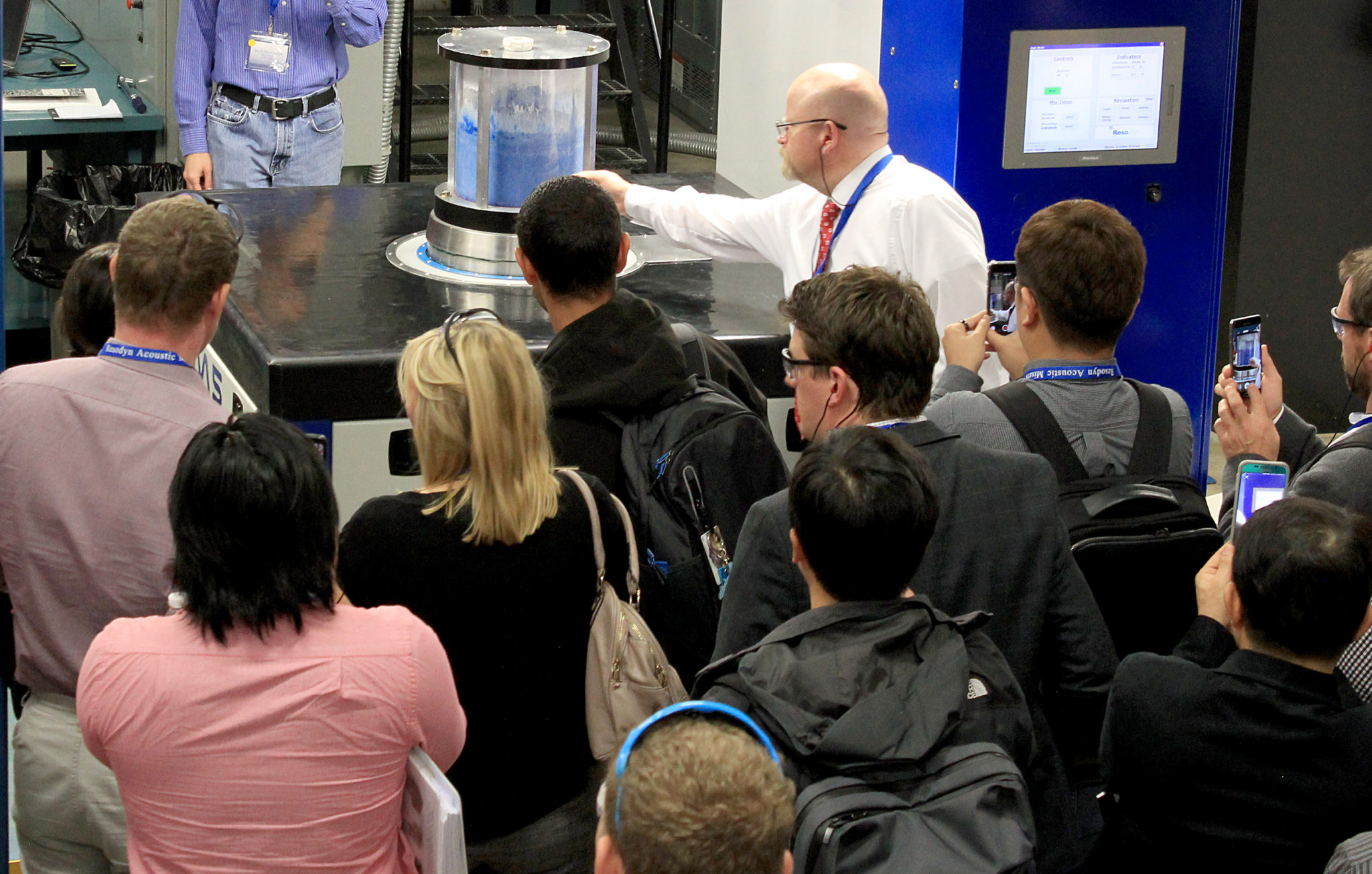

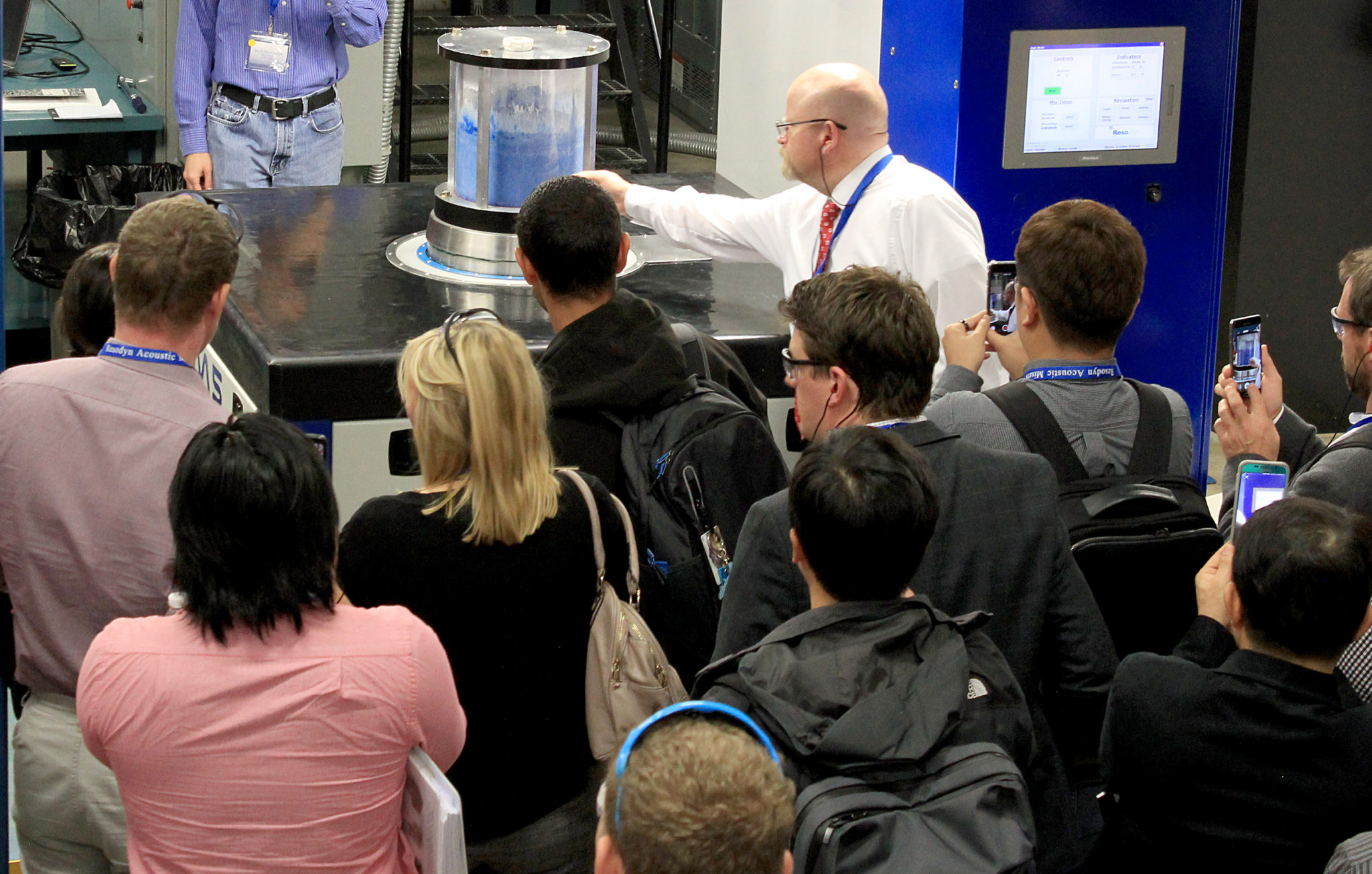

Initial, small-scale mixing tests are designed to prove RAM technology’s processing effectiveness with an efficient test plan approach that is professional, factual, and complimentary. Typical Introductory Mixing Test Features

Effective testing can involve more than rudimentary plan development and materials. Nearly any level of testing can be performed in Resodyn’s development laboratory, as designed by experienced process engineers.Typical Intermediate Mixing Test Features

Sophisticated, developmental and multiple scale tests provide real-world, implementable results that generate benefits with defined scale-up protocol steps. Resodyn’s engineering and in-house processing capabilities are available to accommodate complex, rigorous mixing tests.Typical Scale-Up Testing Features

ResonantAcoustic® Mixing enables the mixing and processing of challenging materials that may not be compatible with conventional or established processes.

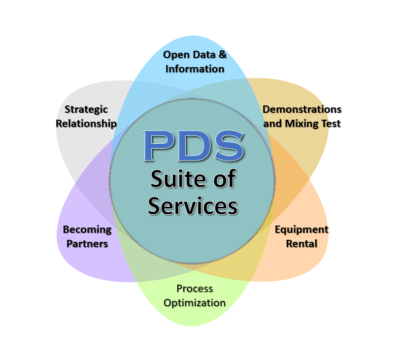

Identifying your future needs, planning for solutions, implementing new processes, and thereby improving profits represent Resodyn’s Process Development Services(SM) portfolio.

Customizing our Services to help align your challenges and goals with RAM solutions is the goal of Process Development Services.

Resodyn customers’ touch on many of the factors below to construct the scale and scope to fit their process development needs. Request our Executive Process Development Services Summary or Call Tibor Egervary, Director of Business Development, to discuss your challenges. 406-497-5333, tibor.egervary@resodyn.com